Let customers speak for us

DTF UV – Advanced Printing for Vibrant and Durable Designs 🌈✨

Take your Direct-to-Film printing to a whole new level with DTF UV technology. This advanced printing method combines the flexibility of DTF with the precision and durability of UV curing, delivering high-quality designs on a variety of surfaces. Perfect for t-shirts, hoodies, bags, and specialty items, Direct-to-Film UV printing ensures vibrant colors, long-lasting adhesion, and a professional finish every time.

What is DTF UV?

Direct-to-Film UV is a Direct-to-Film printing method that uses ultraviolet (UV) light to cure inks directly onto a special film before transferring the design to fabric. Unlike traditional DTF printing, UV curing allows for sharper details, faster drying, and increased durability. This makes it ideal for custom printing businesses, hobbyists, and professional textile manufacturers looking for consistent, high-quality results.

Benefits of Direct-to-Film UV Printing:

-

Vibrant Colors: UV-cured inks produce brighter and more vivid designs that maintain their intensity over time.

-

Durability: Prints are resistant to washing, fading, and cracking, ensuring long-lasting results.

-

Precision: The UV curing process allows for intricate details and high-resolution designs.

-

Fast Production: UV inks dry instantly, reducing wait times and speeding up production workflows.

-

Versatile Applications: Works on various fabrics, including cotton, polyester, and blends, as well as specialty items like leather, canvas, and more.

How Direct-to-Film UV Works:

-

Print your design using UV-curable inks on a DTF film.

-

Cure the printed film using a UV light source to harden the ink.

-

Apply adhesive powder to the cured film to ensure proper transfer.

-

Use a heat press to transfer the design onto your chosen fabric.

-

Peel off the film to reveal a sharp, colorful, and durable print.

Tips for Optimal Results:

-

Always use high-quality UV inks for the best color intensity and adhesion.

-

Ensure the UV curing process is done evenly to avoid incomplete curing.

-

Store films and powders in a dry environment to prevent clumping or damage.

-

Test prints on a small sample to adjust heat press temperature and pressure.

-

Combine with premium DTF transfer powders for superior adhesion and longevity.

Applications of Direct-to-Film UV Printing:

Direct-to-Film UV printing is perfect for personalized apparel, promotional items, and small-scale production. Businesses can create custom t-shirts, hoodies, hats, bags, and more with vibrant designs that stand out. It is especially popular for detailed artwork, logos, and intricate patterns where precision and color quality matter most.

Why Choose Direct-to-Film UV?

With Direct-to-Film UV printing, you get a modern, efficient, and versatile solution for textile and specialty printing. It combines the benefits of traditional DTF printing with the advantages of UV curing, ensuring that every design looks professional and lasts longer. This method reduces waste, improves production efficiency, and allows for high-quality customization across multiple fabric types.

Elevate your printing projects with Direct-to-Film UV – the ideal choice for anyone seeking vivid colors, durability, and precision in every design. Whether for business or personal use, Direct-to-Film UV ensures your creations always look their best and last longer than ever.

Direct-to-Film UV – Advanced Printing for Vibrant and Durable Designs 🌈✨

Take your Direct-to-Film printing to a whole new level with Direct-to-Film UV technology. This advanced printing method combines the flexibility of DTF with the precision and durability of UV curing, delivering high-quality designs on a variety of surfaces. Perfect for t-shirts, hoodies, bags, and specialty items, Direct-to-Film UV printing ensures vibrant colors, long-lasting adhesion, and a professional finish every time.

What is Direct-to-Film UV?

Direct-to-Film UV is a Direct-to-Film printing method that uses ultraviolet (UV) light to cure inks directly onto a special film before transferring the design to fabric. Unlike traditional DTF printing, UV curing allows for sharper details, faster drying, and increased durability. This makes it ideal for custom printing businesses, hobbyists, and professional textile manufacturers looking for consistent, high-quality results.

Benefits of Direct-to-Film UV Printing:

-

Vibrant Colors: UV-cured inks produce brighter and more vivid designs that maintain their intensity over time.

-

Durability: Prints are resistant to washing, fading, and cracking, ensuring long-lasting results.

-

Precision: The UV curing process allows for intricate details and high-resolution designs.

-

Fast Production: UV inks dry instantly, reducing wait times and speeding up production workflows.

-

Versatile Applications: Works on various fabrics, including cotton, polyester, blends, as well as specialty items like leather, canvas, and hard surfaces.

How Direct-to-Film UV Works:

-

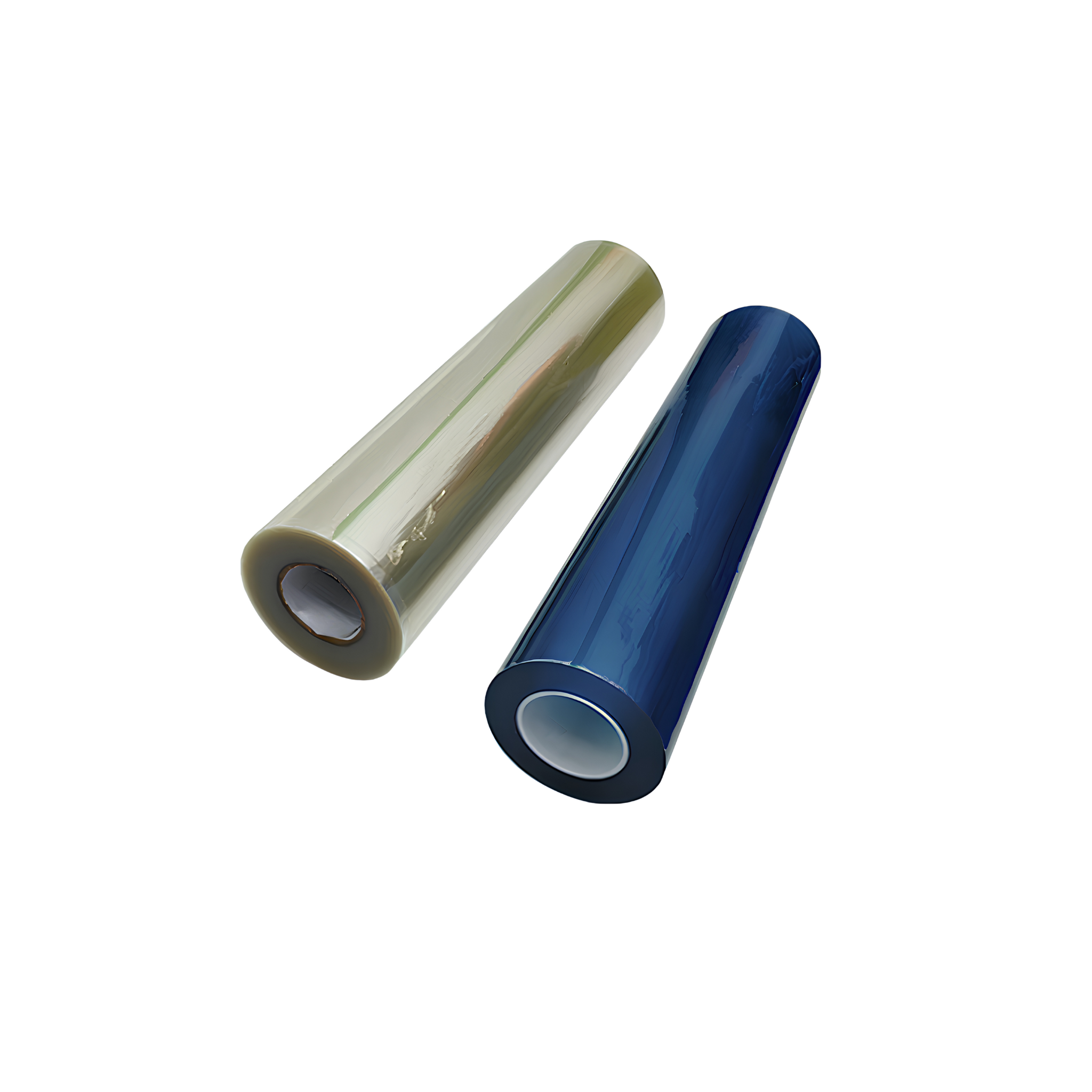

Print your design using UV-curable inks on a DTF film.

-

Cure the printed film using a UV light source to harden the ink.

-

Apply adhesive powder to the cured film to ensure proper transfer.

-

Use a heat press to transfer the design onto your chosen fabric.

-

Peel off the film to reveal a sharp, colorful, and durable print.

Tips for Optimal Results:

-

Always use high-quality UV inks for the best color intensity and adhesion.

-

Ensure the UV curing process is done evenly to avoid incomplete curing.

-

Store films and powders in a dry environment to prevent clumping or damage.

-

Test prints on a small sample to adjust heat press temperature and pressure.

-

Combine with premium DTF transfer powders for superior adhesion and longevity.

-

Consider layering colors or using metallic UV inks for special effects and 3D textures.

Applications of Direct-to-Film UV Printing:

Direct-to-Film UV printing is perfect for personalized apparel, promotional items, home textiles, and small-scale production. Businesses can create custom t-shirts, hoodies, hats, bags, and more with vibrant designs that stand out. Its precision makes it ideal for logos, detailed artwork, or multi-color patterns where color accuracy and clarity are crucial.

Why Choose Direct-to-Film UV?

With Direct-to-Film UV printing, you get a modern, efficient, and versatile solution for textile and specialty printing. It combines the benefits of traditional DTF printing with the advantages of UV curing, ensuring that every design looks professional, lasts longer, and maintains its original brilliance. This method reduces waste, improves production efficiency, and allows for high-quality customization across multiple fabric types.

Elevate your printing projects with Direct-to-Film UV – the ideal choice for anyone seeking vivid colors, durability, and precision in every design. Whether for business or personal use, Direct-to-Film UV ensures your creations always look their best, resist fading, and stand out in a competitive market.