Let customers speak for us

Direct to Film Transfer – High-Quality Custom Printing Solution

Direct to Film (DTF) transfer is a modern method for creating custom designs on apparel and other surfaces. It combines vibrant colors, precise details, and durable prints. This technology is widely used by small businesses, hobbyists, and professional designers. DTF transfers allow complex, full-color graphics to be applied easily and consistently. With this method, creators can produce high-quality custom products without large setup costs or specialized equipment.

What Is Direct to Film Transfer?

Direct to Film transfer is a process where designs are printed onto a special film using DTF printers. After printing, an adhesive powder is applied to the design. A heat press is then used to transfer the design onto the final surface. The result is a durable and vibrant print that adheres well to fabrics and other materials. DTF works on cotton, polyester, blends, and even non-fabric surfaces like mugs, wood, and acrylic.

Why Choose Direct to Film Transfer?

1. Vibrant and Long-Lasting Prints

DTF transfers produce prints with bright, vivid colors. The images maintain sharp details and do not fade easily. The adhesive ensures that designs remain intact even after multiple washes or heavy use. This makes DTF transfers ideal for both personal and commercial projects.

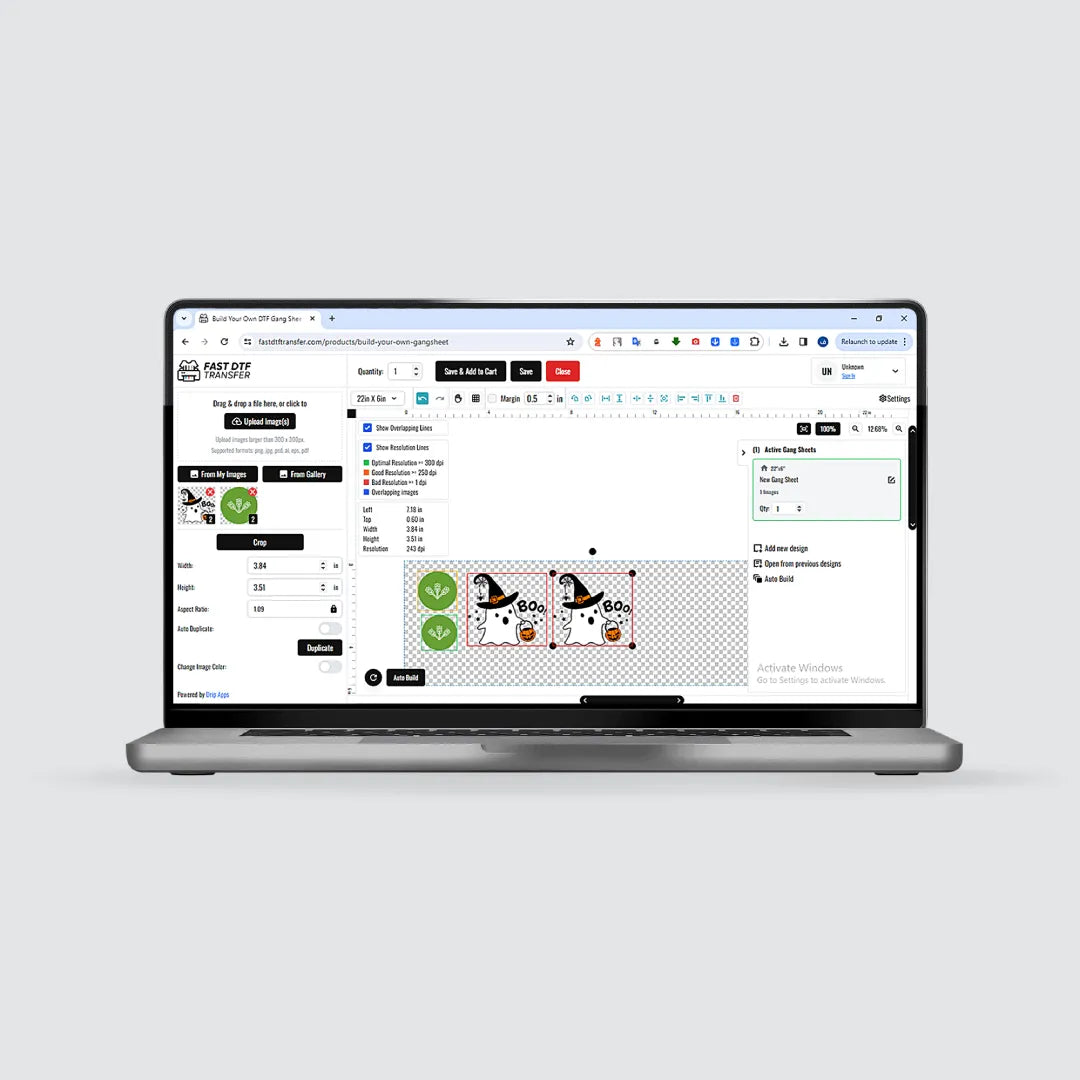

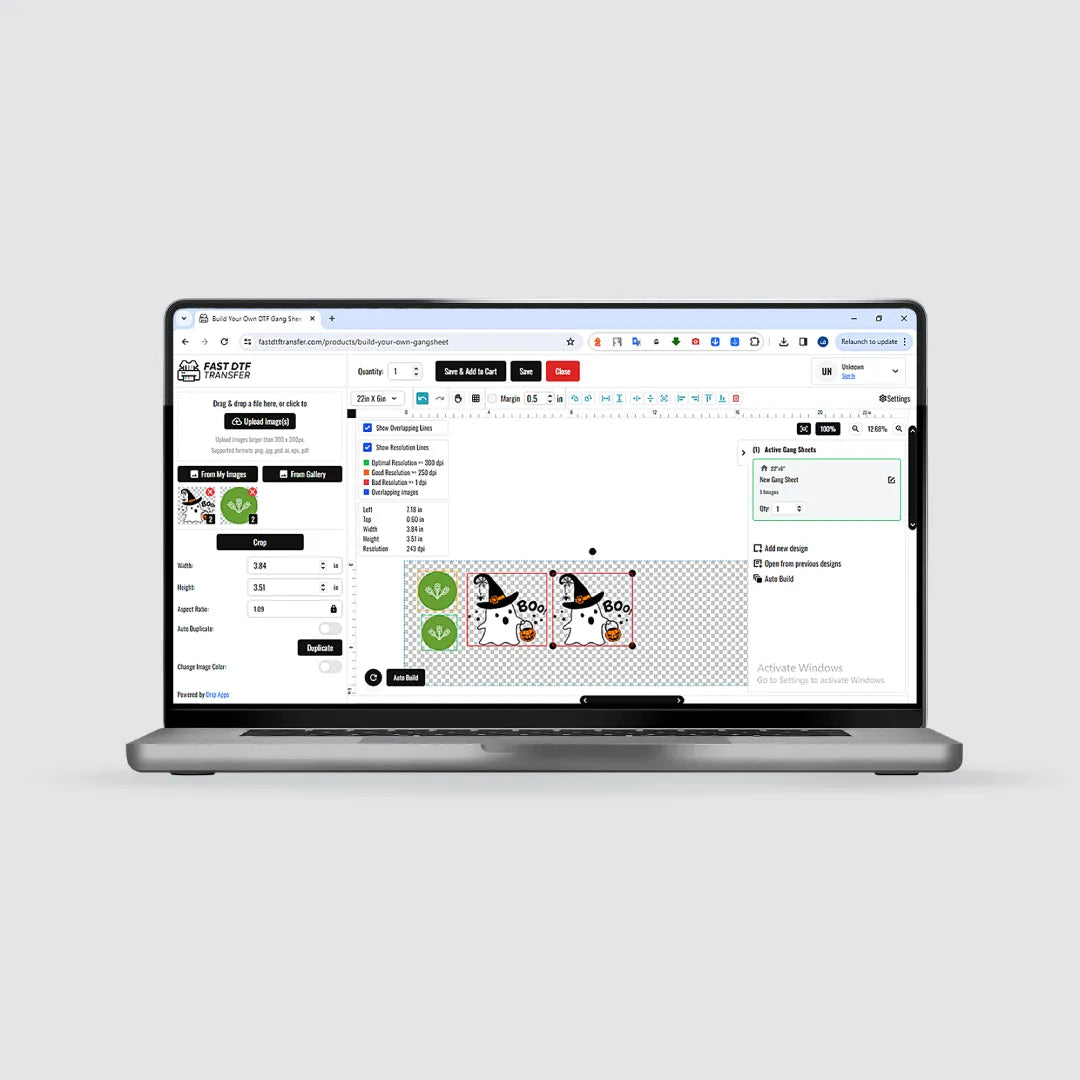

2. Easy to Use

The application process is simple and accessible. Users peel the backing, place the design on the target surface, and press it using heat. No complex equipment or skills are needed. This makes DTF transfers suitable for beginners and small businesses looking for professional-quality results.

3. Versatility

DTF transfers can be applied to a wide variety of materials. T-shirts, hoodies, tote bags, hats, and other apparel can be customized. Non-fabric items like mugs, phone cases, and wooden products are also compatible. This flexibility allows creators to expand their offerings without needing multiple printing methods.

4. Cost-Effective

DTF transfers have low setup costs. There is no need for screens, plates, or specialized machinery. Small batches and single-item orders are feasible, making it an affordable option for startups and individual creators.

How Direct to Film Transfer Works

-

Design Printing

The artwork is printed onto a special DTF transfer film using a printer. This process captures all colors and fine details. -

Applying Adhesive Powder

Adhesive powder is applied over the printed design. It ensures the design bonds firmly to the final surface during heat transfer. -

Heat Pressing

The film is pressed onto the surface using a heat press. The adhesive melts and bonds the design securely to the material. -

Final Product

The finished product features a smooth, vibrant, and long-lasting design. It is ready for use or sale immediately after pressing.

Applications of DTF Transfer

Custom Apparel

DTF transfers are ideal for t-shirts, hoodies, and sweatshirts. They allow intricate designs and multi-color graphics to be applied with ease. The prints are durable and resist fading, cracking, or peeling.

Promotional Products

Businesses can create branded merchandise using DTF transfers. Tote bags, hats, mugs, and other promotional items can feature high-quality designs. This method is excellent for corporate giveaways, marketing campaigns, and events.

Personal Gifts

DTF transfers are perfect for personalizing gifts. Birthday, holiday, or anniversary items can be customized with names, dates, or special graphics. The process is fast, making it easy to create multiple items at once.

Event Merchandise

Events such as sports tournaments, school functions, and fundraisers benefit from DTF transfers. Multiple designs can be applied to different products efficiently, allowing large orders to be completed quickly.

Benefits for Businesses

-

Quick Production: Reduce printing time with multiple items per batch.

-

No Minimum Orders: Print small batches or individual products.

-

Consistent Quality: Maintain sharp, vibrant designs across all items.

-

Reduced Waste: Use film and ink efficiently.

-

Versatile Application: Works on various fabrics and surfaces.

These advantages make DTF transfers a smart choice for businesses looking to scale their operations without sacrificing quality.

Why DTF Transfer Is a Smart Choice

DTF transfers offer high-quality results, ease of use, and cost efficiency. The technology supports intricate, multi-color designs with durable adhesion. Businesses can produce custom apparel and promotional products quickly and consistently. Hobbyists can create personalized gifts with professional-looking results. With flexibility across materials and surfaces, DTF transfers provide a modern and reliable solution for custom printing.

Conclusion

DTF transfer is a versatile and efficient method for producing custom items. Its vibrant, durable prints and easy application make it suitable for apparel, promotional items, personal gifts, and event merchandise. Small businesses, creators, and hobbyists benefit from reduced production costs, minimal setup, and consistent results. With the ability to print complex designs on a variety of surfaces, DTF transfers are an ideal choice for anyone looking to create high-quality custom products efficiently and professionally.

Direct to Film Transfer

Please Click to get P604U - UV DTF Printer

Please Click to get DTF Ink