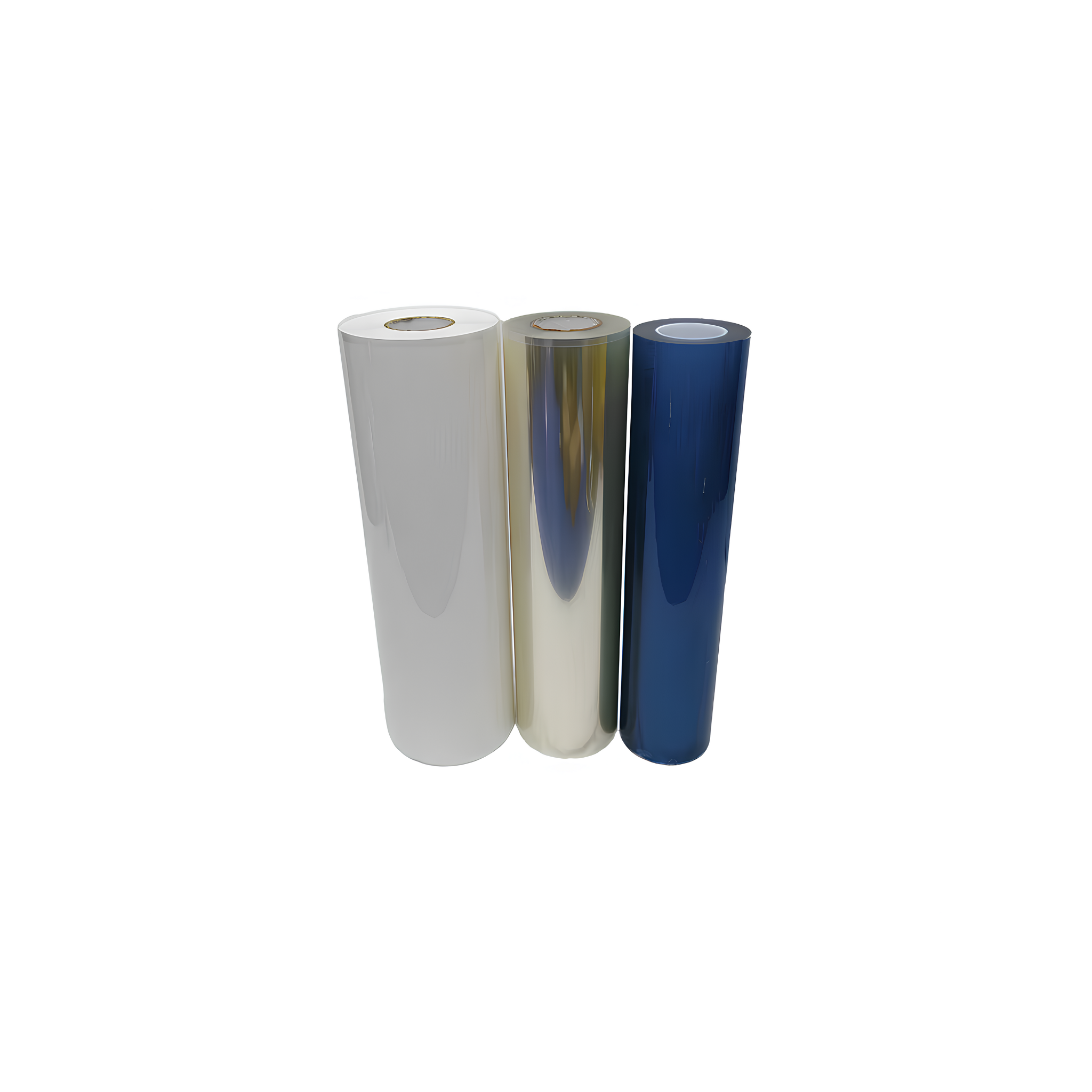

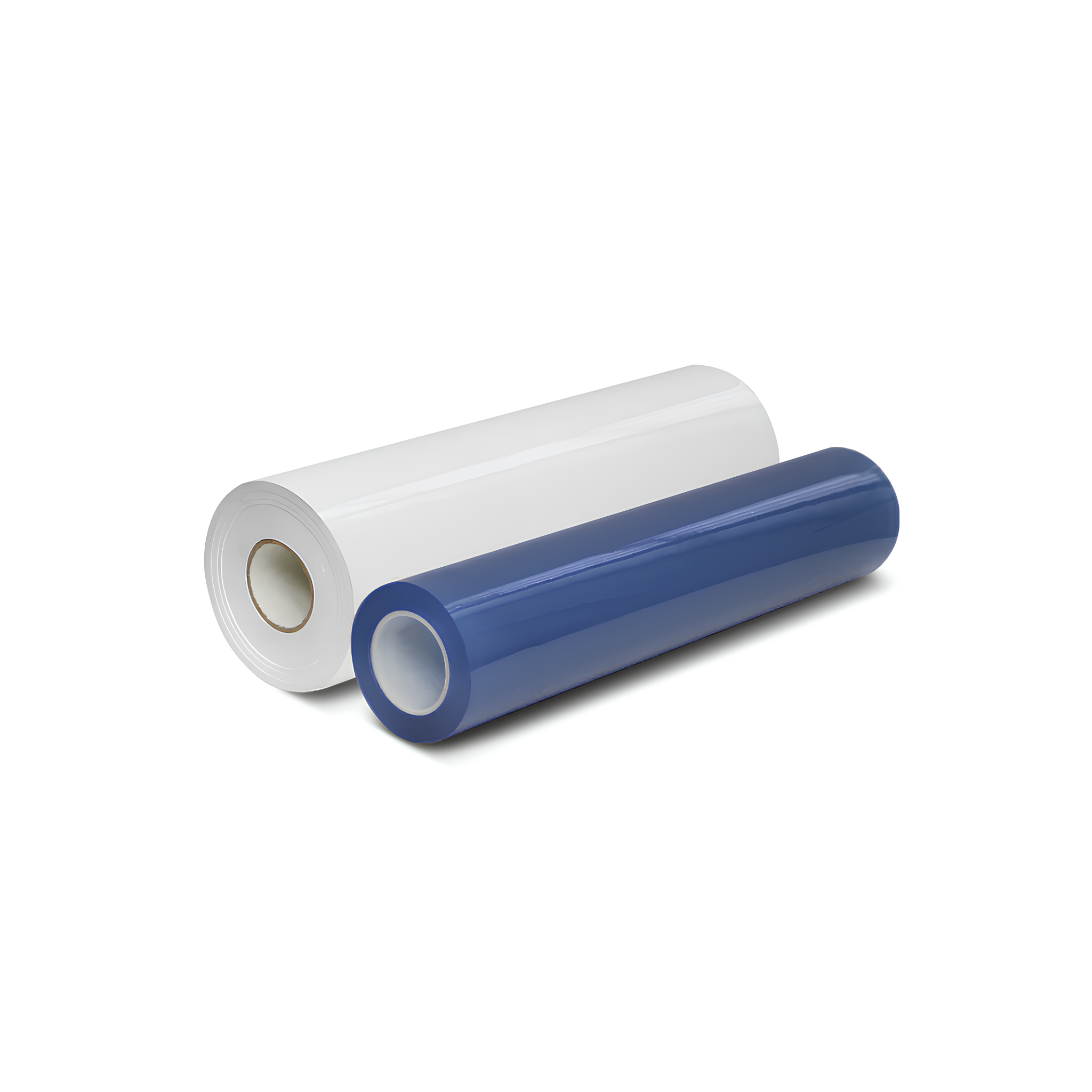

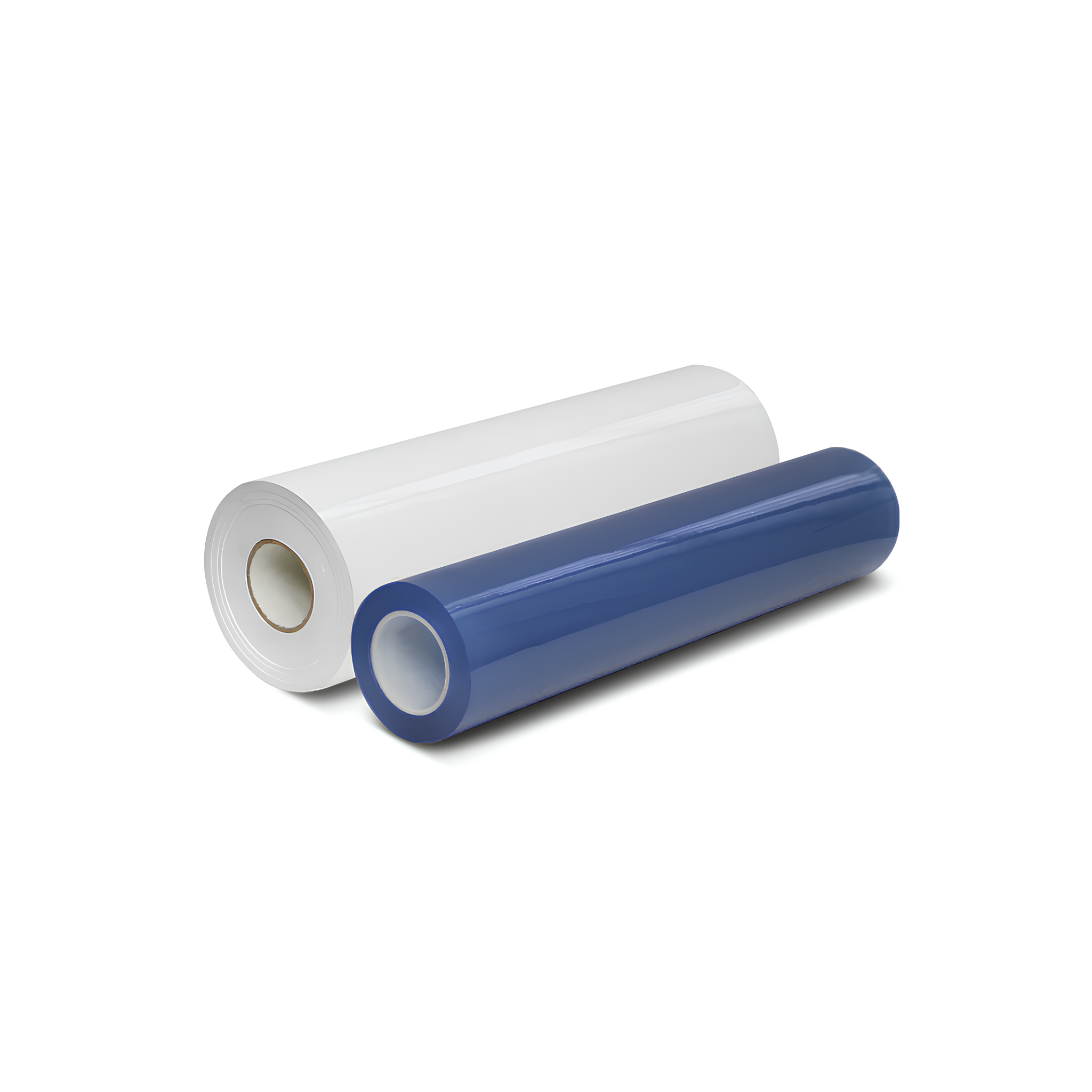

UV DTF A&B Film Roll - 24" 325'

Pickup currently unavailable at Fast DTF Transfer Garfield

UV DTF A&B Film Roll - 24" 325'

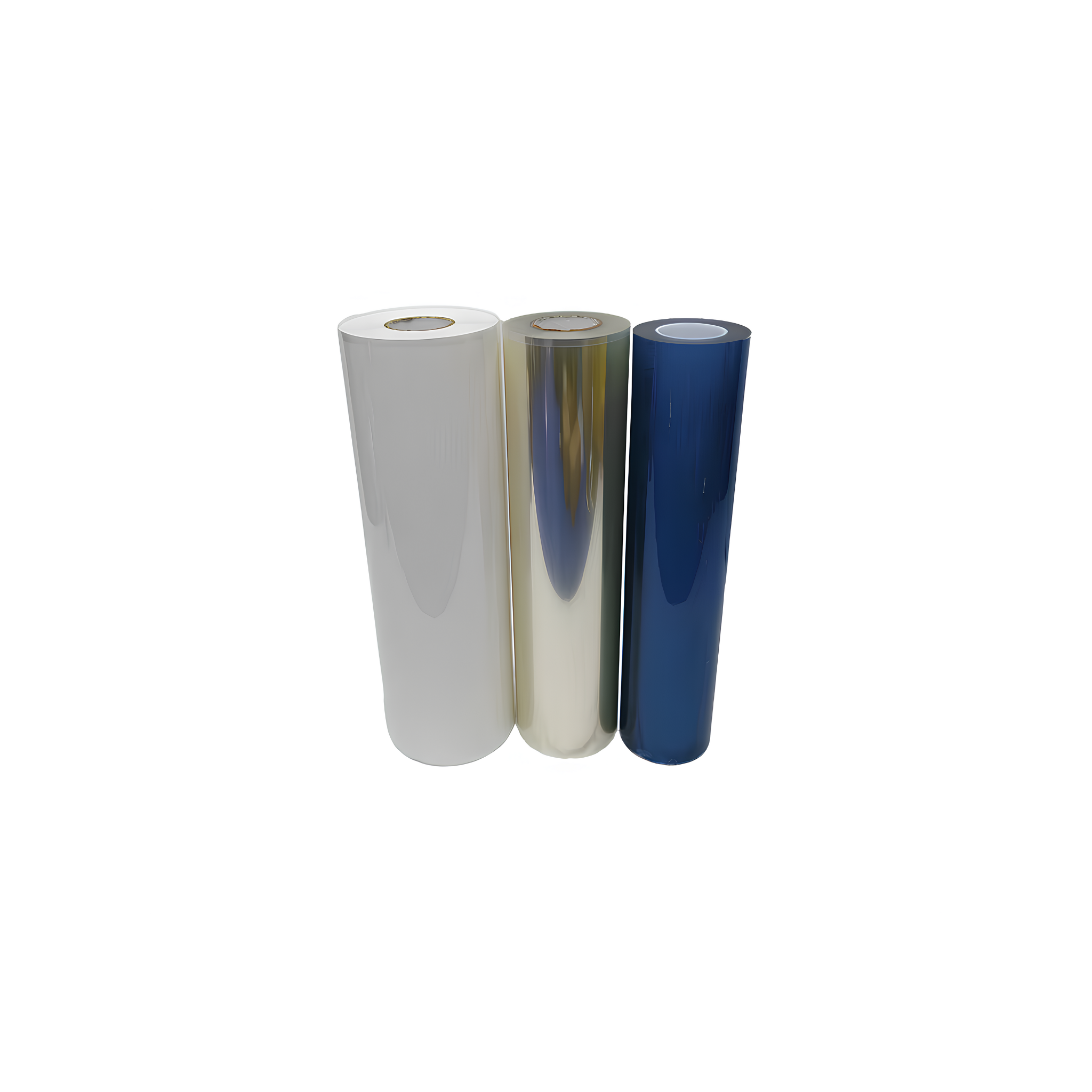

Clear

Fast DTF Transfer Garfield

66 Belmont Avenue

Unit A

Garfield NJ 07026

United States

Fast Dtf Transfer Whippany

1 Apollo Drive

Unite D

Whippany NJ 07981

United States

The Industrial Standard for Hard Surface Branding UV DTF Film Roll

The world of custom printing is expanding beyond fabric. For businesses targeting hard surfaces, the UV DTF Film Roll has become a vital asset. This technology allows you to create high-quality decals for glass, metal, and plastic. Unlike standard stickers, these transfers offer a premium, embossed feel. They are durable, vibrant, and extremely easy to apply. This guide will explore why the 24" by 325' roll is the perfect choice for professional production environments.

What is a UV DTF Film Roll?

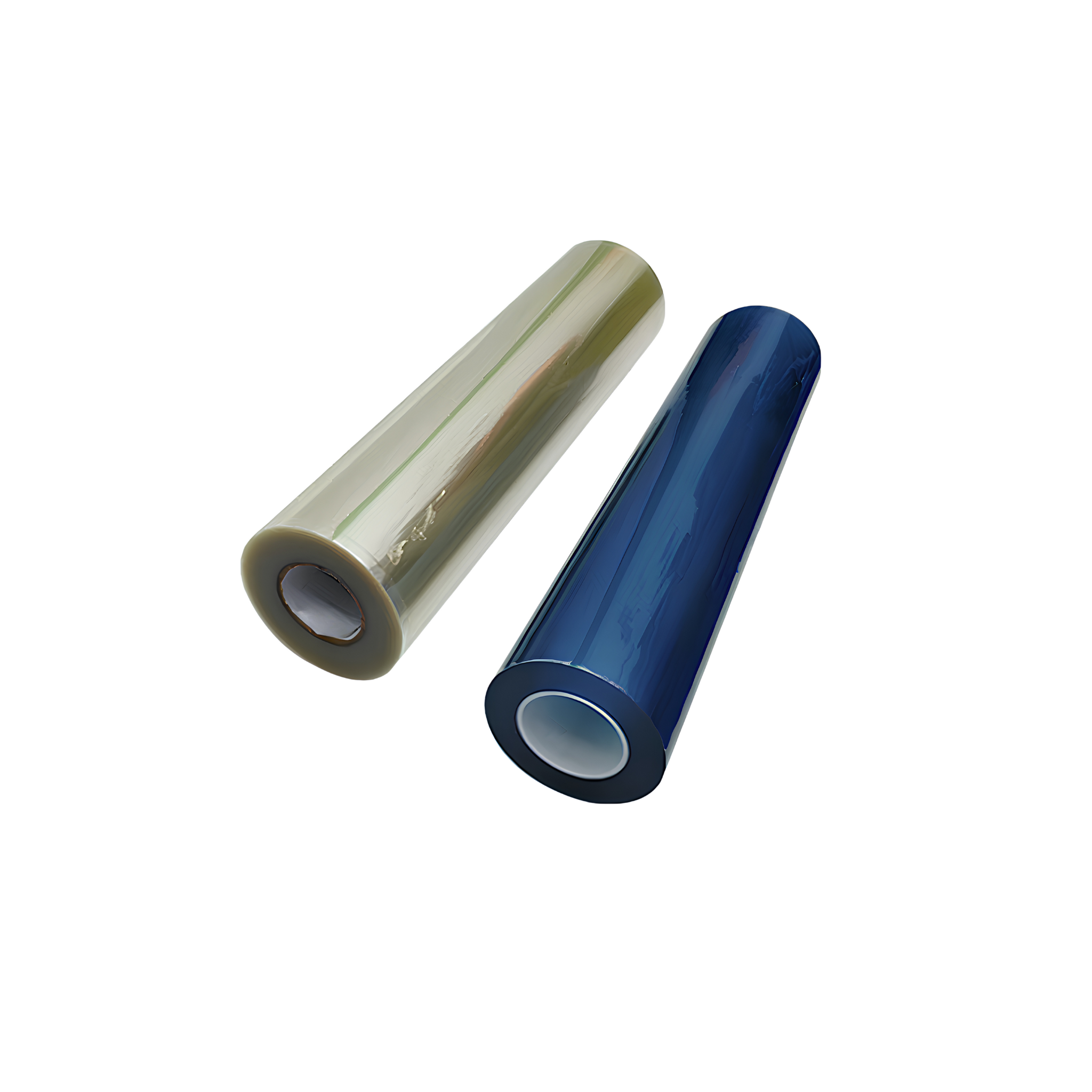

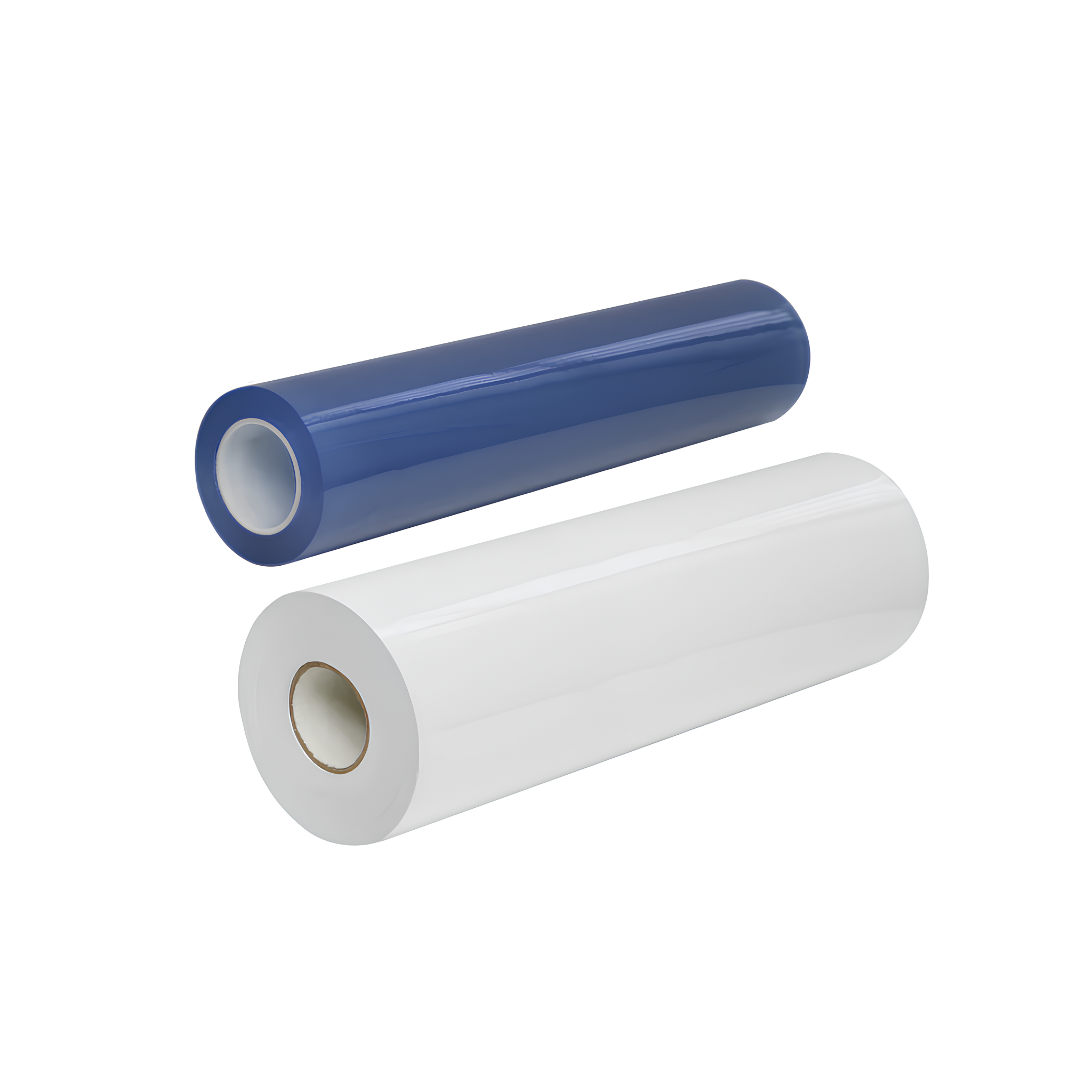

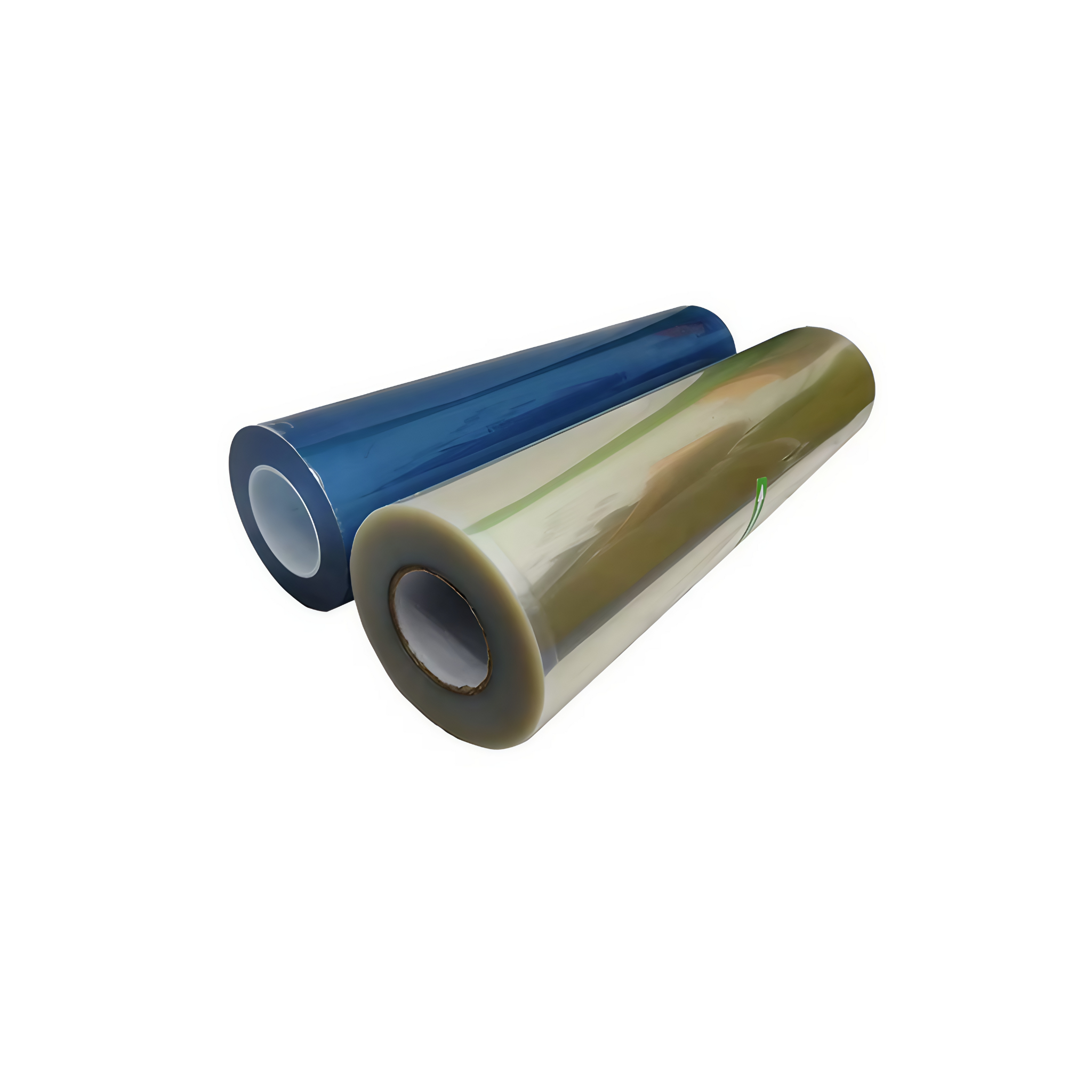

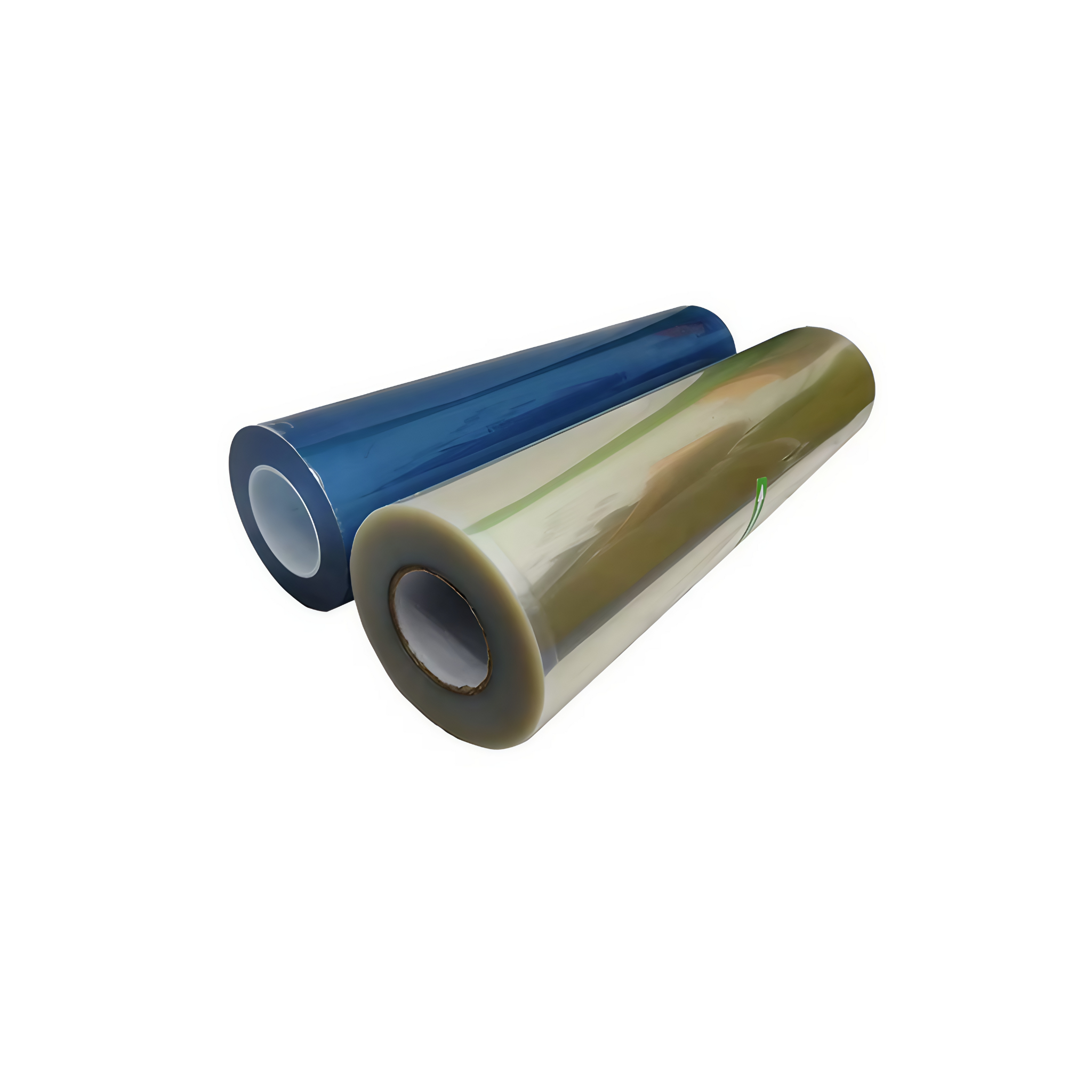

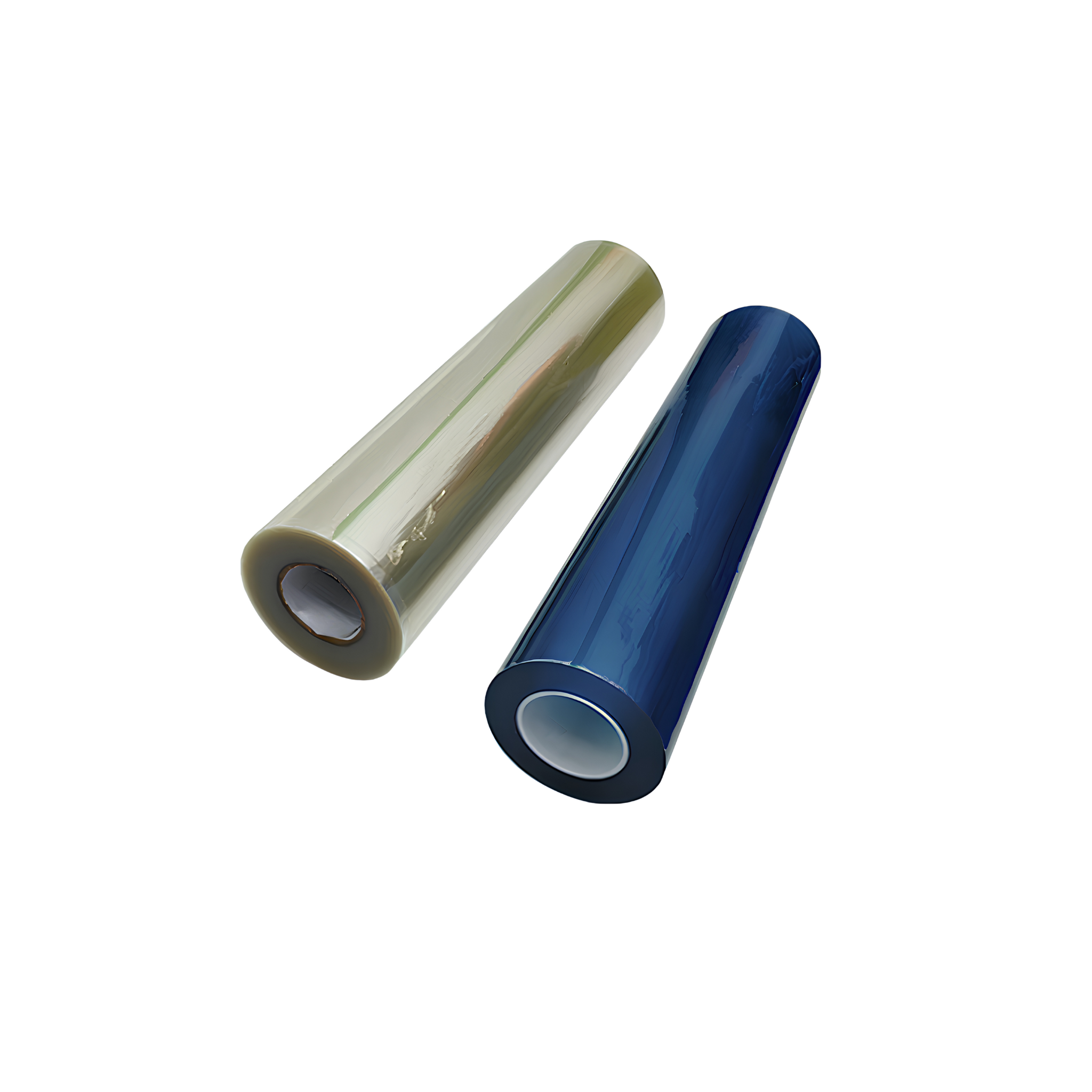

A UV DTF Film Roll system consists of two distinct parts: Film A and Film B. Together, they create a "rub-on" transfer that requires no heat to apply.

The Role of Film A (The Printing Base) Film A is the carrier sheet where the printing happens. Your UV printer deposits CMYK inks, white ink, and a clear varnish directly onto this film. The varnish provides the signature 3D texture and protective layer.

The Role of Film B (The Transfer Film) Film B is the laminating layer. After Film A is printed, it passes through a laminator where Film B is applied. This film picks up the ink and adhesive from Film A. When you are ready to use the decal, you peel Film B, and the design comes with it.

Why the 24" 325' Size Matters

Choosing the right size for your UV DTF Film Roll is crucial for efficiency. The 24-inch width is considered the industrial sweet spot.

High-Volume Production A 24-inch wide roll allows you to "gang" many designs together. You can print hundreds of small logos or dozens of large wraps across the width. This reduces wasted space and maximizes your output per hour.

Long-Term Consistency The 325-foot length ensures you can run large jobs without stopping. Frequent roll changes slow down production and increase the risk of errors. With a long roll, you achieve a consistent tension throughout the print run. This leads to better registration and fewer alignment issues.

Advantages of Using UV DTF Technology

Many branding experts are switching to UV DTF Film Roll products over traditional vinyl or pad printing. The benefits are clear and immediate.

No Heat Required Standard DTF requires a heat press, which limits it to fabrics. UV DTF is a cold transfer process. This means you can brand items that would melt under heat, such as thin plastics or delicate electronics.

Incredible Durability UV-cured inks are naturally tough. Once applied, these transfers are water-resistant and scratch-resistant. They can withstand daily use on items like phone cases, water bottles, and tools. The varnish layer acts as a shield against fading from sunlight.

The 3D Embossed Effect One of the most popular features is the tactile feel. By layering the ink and varnish, the design sits slightly above the surface. This gives the product a high-end, custom-manufactured look that flat stickers cannot match.

Step-by-Step Production Process

Using a Film Roll requires a specific workflow to ensure the adhesive bonds correctly.

-

Printing on Film A: Set your UV printer to the correct profile. Ensure the white ink and varnish channels are firing correctly.

-

Lamination: Feed the printed Film A into a cold laminator along with Film B. The pressure must be even to avoid air bubbles.

-

Cutting: Once laminated, you can cut the individual decals using a scissors or a digital cutter.

-

Application: Clean the target surface with alcohol. Peel the design away from the backing (Film A) using Film B.

-

Transfer: Press the design onto the surface and rub firmly with your thumb or a squeegee.

-

The Final Peel: Slowly remove Film B. The design will remain permanently bonded to the object.

Target Markets for UV DTF Transfers

Investing in a Film Roll opens up many new revenue streams. You are no longer limited to just apparel.

-

Promotional Products: Create branded mugs, tumblers, and pens with ease.

-

Tech Accessories: Brand laptops, power banks, and phone cases with high-detail logos.

-

Interior Signage: Apply directional signs or logos directly to office windows and doors.

-

Industrial Labeling: Produce durable serial number plates or safety warnings for machinery.

Maintenance and Storage Tips

To get the most out of your Film Roll, proper storage is essential. These films are sensitive to their environment.

Avoid High Humidity Moisture can affect the adhesive properties of the film. Always store your rolls in a dry, climate-controlled room. Keeping them in their original plastic wrapping when not in use is a good practice.

Keep Away from Dust Because UV printing relies on static and fine ink droplets, dust is a major enemy. A dusty roll can cause "pinholes" in your print. Ensure your printing area is clean and the roll is covered.

Temperature Control Extreme heat can cause the adhesive on the film to become tacky or degrade. Store your rolls upright to prevent "flat spots" and keep them away from direct sunlight or heaters.

Common Troubleshooting Issues

If you encounter problems with your Film Roll, check these common factors:

-

Bubbles During Lamination: This usually means the laminator pressure is too low or the speed is too high.

-

Design Not Peeling: Ensure the white ink layer is thick enough to provide a solid base for the adhesive.

-

Ink Cracking: This happens if the varnish layer is too brittle. Adjust your UV lamp intensity or check the ink expiration date.

Conclusion

The Film Roll (24" 325') is an essential tool for any modern printing business. It offers a bridge between digital convenience and industrial durability. With the ability to print on almost any hard surface, your growth potential is limitless. By choosing the 24-inch wide format, you ensure maximum efficiency and minimal waste. Embrace the future of hard-surface branding and deliver results that your customers can see and feel.

Join our growing community online to stay updated with the latest trends and innovations in the printing world. Follow us on

Maintaining a competitive edge in the custom apparel industry requires a balance between speed and high-end quality. Modern printing solutions allow creators to bypass the limitations of traditional setups, making it easier than ever to produce intricate, full-color designs on demand. If you are looking to elevate your brand with retail-ready durability and vibrant finishes, you can explore the

The longevity and performance of a digital printer depend heavily on a consistent and precise maintenance routine. Since ink residue can quickly accumulate on sensitive components like printheads and capping stations, using the right tools is essential to prevent costly clogs and hardware damage. To ensure a thorough clean without leaving lint or fibers behind, you should utilize professional-grade supplies. You can get the

Choose options