What is DTF Transfer

What is DTF Transfer ? A Complete Guide to Direct to Film Printing

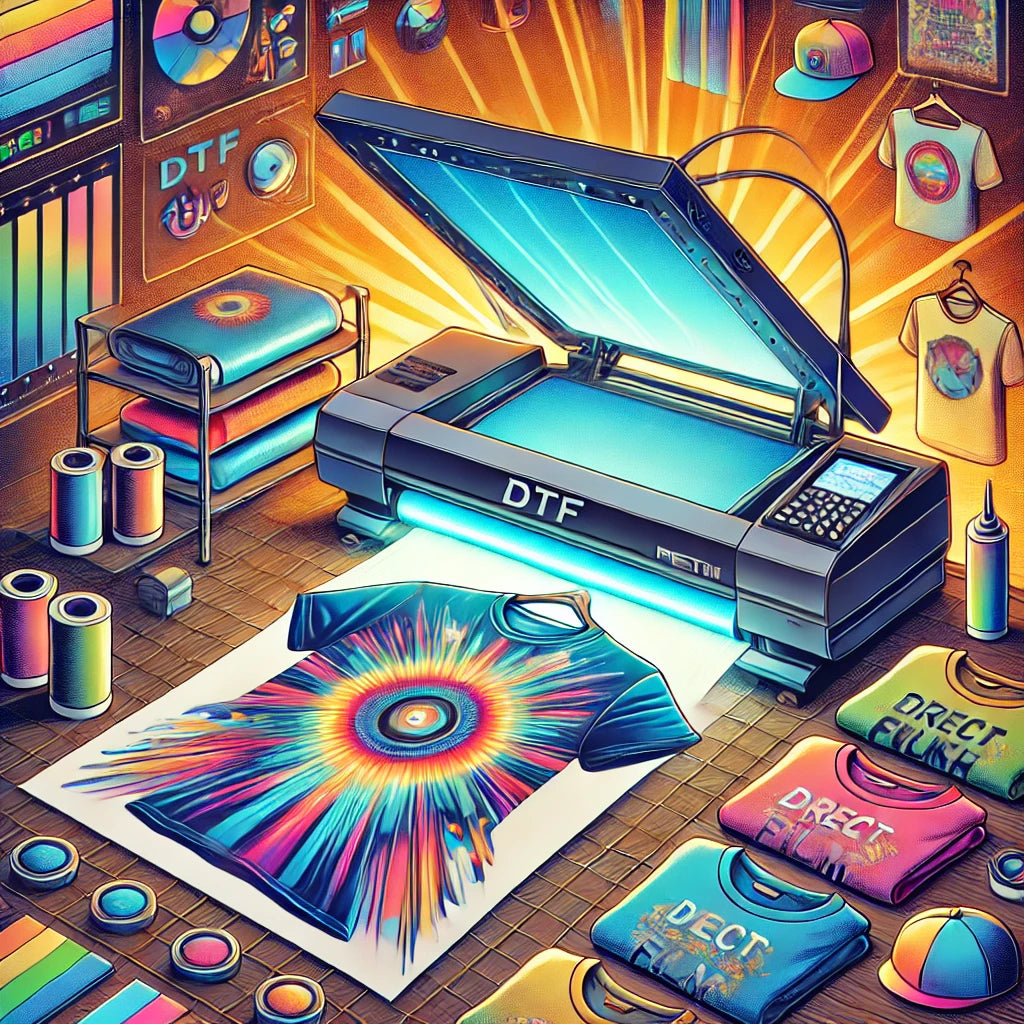

What is DTF Transfer DTF stands for Direct to Film. It's a modern way to print designs on fabric. This method prints on a special PET film using water-based inks. The design is then heat-pressed onto different types of fabric. Unlike screen printing or sublimation, no pre-treatment is needed. That makes it fast, easy, and very flexible.

✅ What is DTF Transfer & Why It Matters?

People often ask, “What is DTF Transfer?” because they want to know how it compares to other methods.

Here’s why DTF stands out:

-

Prints photo-quality, full-color graphics

-

Works on cotton, polyester, and blends

-

Wash-resistant—no cracking or peeling

-

Supports light and dark fabrics

-

No cutting or weeding—just print and press

🔧 How Does the DTF Transfer Process Work?

To answer "what is DTF transfer" completely, let’s break down the steps:

1. Design Creation

Create your artwork using Photoshop or Illustrator. Use CMYK color mode.

2. Print on PET Film

Print your image in mirror mode. The white ink layer is added last.

3. Apply Adhesive Powder

Sprinkle hot melt powder onto the wet print. Shake off the excess.

4. Cure the Powder

Use a heat press or oven. This melts the powder into the ink.

5. Heat Press the Design

Place the film on the fabric. Press at 300–325°F for 10–15 seconds.

6. Cold Peel & Finish

Let the film cool. Then peel it off. Press again for extra durability (optional).

🎯 Where Can You Use DTF Transfers?

DTF transfer is perfect for:

-

Custom T-shirts and hoodies

-

Tote bags, hats, and caps

-

Corporate uniforms

-

Branded event merchandise

-

Etsy and Shopify stores

It’s great for small or growing businesses. You can scale fast without big machines.

🛠️ DTF vs. Other Methods

Why choose DTF?

-

No fabric pretreatment (unlike DTG)

-

Full-color prints with white ink

-

Works on many fabric types

-

Soft, flexible, and long-lasting

-

Great for small or on-demand orders

How does this garment printing method compare to traditional screen printing?

Unlike screen printing, this newer method does not require burning screens or applying color layers manually. Instead, designs are printed onto a special film and heat-transferred onto fabric. This reduces setup time and is ideal for small batches or custom orders. It also supports full-color images and gradients, which are harder to achieve with traditional techniques. Small businesses and hobbyists often find it more accessible because it requires less space and fewer tools.

Is this process suitable for printing on different types of fabric?

Yes, this printing approach works on a wide range of textiles, including cotton, polyester, blends, and even nylon in some cases. Since the design is applied via heat and adhesive powder, it adheres well to various textures and fabric weights. This makes it a flexible option for apparel printing, especially when you're working with mixed material inventories. Whether it's a lightweight summer tee or a thick cotton hoodie, the final print remains vibrant and durable.

What kind of equipment do I need to get started?

To begin with this type of printing, you’ll need a compatible printer (usually modified inkjet or a purpose-built machine), special water-based pigment inks, transfer film, adhesive powder, and a heat press. Optional tools include a curing oven and a shaker for applying powder evenly. While this might sound like a lot, many beginner-friendly kits are available on the market, and the investment is often lower than other professional print methods. Once set up, the workflow is smooth and relatively fast.

How durable are the prints over time?

Prints made with this method are known for their excellent durability. They typically hold up well after 40 to 50 washes when proper heat and pressure settings are used. The adhesive melts into the fabric fibers, making it resistant to cracking, peeling, or fading. To prolong print life, washing the garment inside out on cold and air drying is recommended. This makes it ideal not only for custom fashion but also for uniforms and promotional wear that must withstand frequent use.

Can I use this technique for selling custom merchandise online?

Absolutely. Many online sellers use this printing method for dropshipping, Etsy shops, and small apparel brands. It enables on-demand printing, so you don’t need to keep large inventories. Designs can be created digitally and printed as orders come in. This reduces waste and upfront costs, allowing for more design freedom and personalization. It’s especially useful in the current print-on-demand economy, where flexibility and speed are key.