What is a DTF Transfer

What is a DTF Transfer?

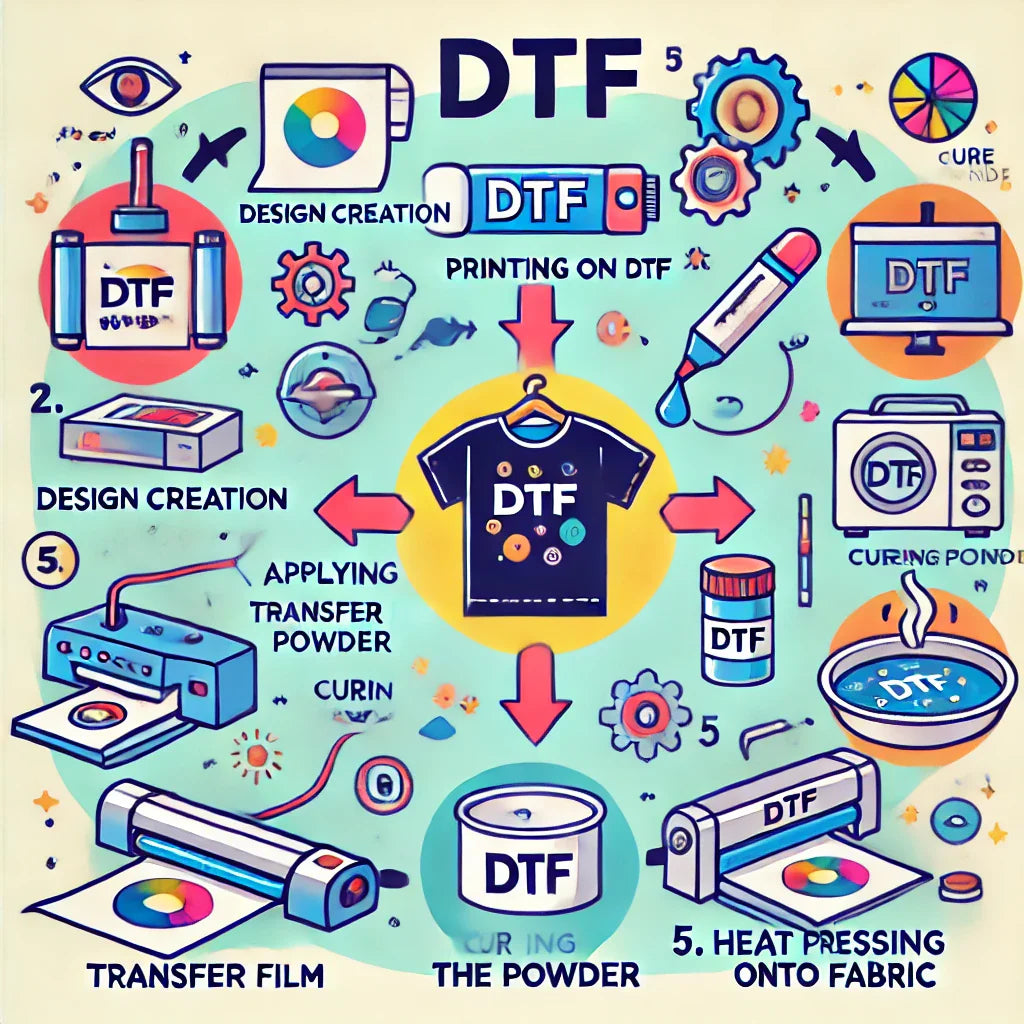

How Does DTF Transfer Work?

The DTF Transfer process begins with creating a design, which is then printed onto a film using a specialized printer. However, the printed film is applied to the fabric using heat and pressure, allowing the design to transfer permanently onto the material. This method produces sharp details and vibrant colors, making it suitable for a wide range of applications. Also, it is highly versatile, as it can be used on various fabrics such as cotton, polyester, and even non-fabric surfaces like bags and accessories.

Steps in the DTF Transfer Process:

- Design Preparation: Create your design using compatible software.

- Printing: The design is printed onto a special transfer film using a DTF printer.

- Transfer: The printed film is placed on the fabric and heat is applied to transfer the design.

- Heat Application: The design is permanently adhered to the fabric through the heat press. However, this process ensures the print is durable and long-lasting. Additionally, the use of heat ensures that the design adheres well to the fabric, even after multiple washes.

This process is efficient and allows for high-quality prints on a variety of fabrics and surfaces, making a favorite among users.

Benefits of DTF Transfer

Offers numerous advantages for both professional and amateur users. Some of the key benefits include:

- High Quality: Delivers vibrant colors and fine details with precision.

- Versatility: Can be used on a variety of fabrics and surfaces.

- Cost-Effective: A more affordable alternative to other printing methods.

- Fast Production: Quick transfer process, saving time and resources. However, the process does not compromise on quality, making it ideal for both small and large production runs. Additionally, it offers consistent results across different material types.

Applications of DTF Transfer

İs widely used across various industries, including fashion, promotional products, and personalized gifts. Here are some common applications:

- T-Shirt Printing: Perfect for creating custom t-shirts with high-quality designs.

- Gift Items: Ideal for transferring personalized designs onto gift products.

- Industrial Apparel: Used for printing on uniforms, work clothes, and other industrial items.

- Accessories: Designs can be transferred to bags, hats, and other accessories. However, the flexibility of DTF Transfer extends to other items like shoes, aprons, and home textiles. Additionally, this technology can be used to personalize items for special events such as weddings, corporate giveaways, and sports team merchandise.

Advantages and User Reviews of

Users of technology have reported great satisfaction with the results. The prints are durable, and the colors remain vibrant even after washing. Here are some customer reviews:

- "I’ve been using for my custom t-shirts, and they have held up incredibly well, even after multiple washes!" - John Smith

- "The printing process was fast and the quality was superb. Highly recommend it for anyone looking to print on fabric." - Sarah Lee

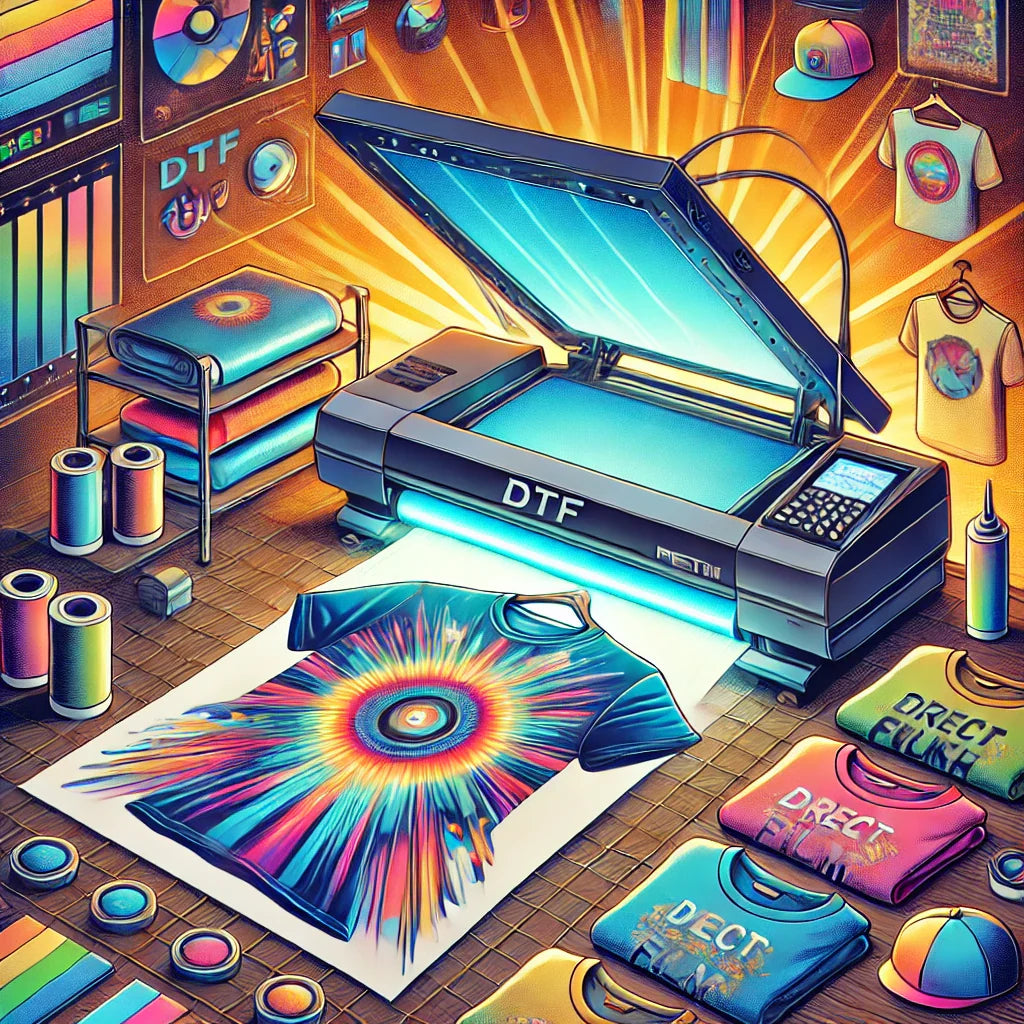

The Role of in the Printing Industry

Has revolutionized the printing industry by offering an easy-to-use and efficient method for creating high-quality prints. Whether for personal use or business applications, this technology provides users with a cost-effective way to produce vibrant and long-lasting designs on a wide range of materials.

Conclusion

Technology is a game-changer for anyone looking to create high-quality, durable prints on various fabrics and surfaces. It offers a fast, flexible, and cost-effective solution, making it a popular choice among both small business owners and hobbyists.

1. What is DTF Transfer?

DTF (Direct-to-Film) Transfer is a printing method where designs are first printed onto a special film and then transferred onto fabric or other materials using heat and pressure. This method offers high-quality, vibrant prints and is versatile for various applications.

How does the process work?

The process involves four main steps:

- Design Preparation: Create your design using compatible software.

- Printing: Print the design onto a special transfer film using a DTF printer.

- Transfer: Place the printed film on the fabric.

- Heat Application: Apply heat using a heat press to permanently transfer the design onto the fabric.

What are the advantages of ?

Some key benefits of include:

- High-quality prints with vibrant colors.

- Versatility, as it can be used on various fabrics and surfaces.

- Cost-effective compared to other printing methods.

- Fast production time.

Can be used on all fabrics?

Yes, is highly versatile and can be used on a wide variety of fabrics, including cotton, polyester, and blends. It is also suitable for non-fabric surfaces such as bags and accessories.

Is durable?

Yes, the prints created using are durable and long-lasting. They can withstand washing and regular wear without significant fading or cracking.

Do I need special equipment for ?

Yes, you will need a DTF printer, a special transfer film, and a heat press machine to apply the design onto the fabric.

How long does the process take?

The entire process is relatively quick. Depending on the size of the design, it typically takes a few minutes to print and transfer the design, making it ideal for small to medium-sized production runs.

Can I print multiple colors with ?

Yes, allows for printing designs with multiple colors, ensuring that your prints are as vibrant and detailed as needed.

Is Environmentally friendly?

Can be considered more environmentally friendly compared to traditional screen printing methods because it uses less water and fewer chemicals. However, like all printing methods, it’s essential to properly dispose of used materials to reduce environmental impact.

Where can I buy materials and equipment?

Printers, films, and heat press machines are available from various online retailers, specialized printing suppliers, and local distributors. Be sure to choose high-quality materials for the best results.