How to Make DTF Transfer

How to Make DTF Transfer: A Step-by-Step Guide

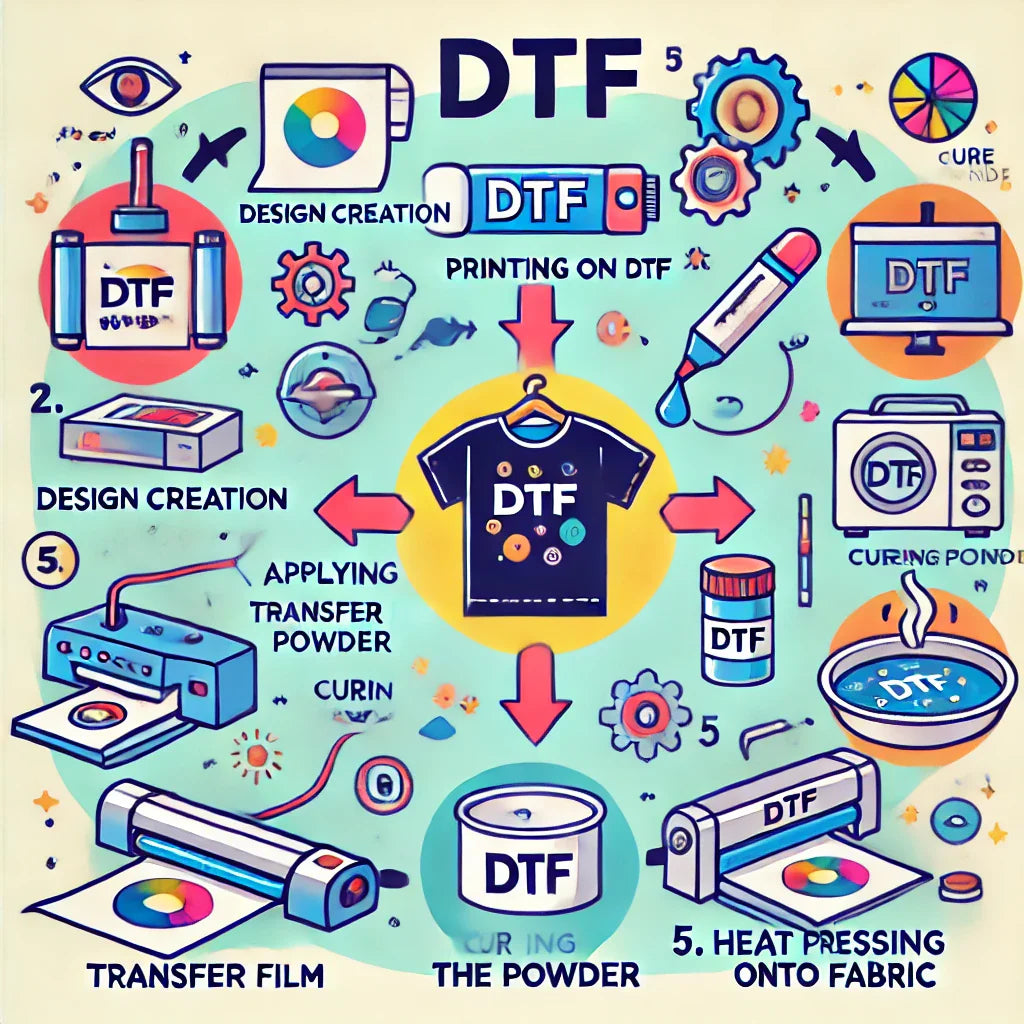

DTF (Direct to Film) transfer printing is a popular method for transferring high-quality, vibrant designs onto various materials, including fabrics, bags, and accessories. Unlike traditional heat transfer methods, DTF allows for the easy application of detailed and full-color designs without the need for cutting or weeding. Below is a comprehensive guide on how to make DTF transfers.

Prepare Your Design

The first step in making a Direct to Film transfer is creating your design. To do this, you will need graphic design software like Adobe Illustrator, Photoshop, or CorelDRAW. You should follow these essential guidelines to ensure the best results:

- Resolution: Set the design resolution to 300 DPI for high-quality prints.

- Color Format: Use CMYK color mode to ensure accurate color reproduction.

- Size: Make sure the design size matches the surface it will be applied to, such as t-shirts, bags, etc.

Additionally, it’s important to use a transparent background to avoid unwanted borders around your design, ensuring a clean transfer.

Print the Design

After finalizing your design, it’s time to print it onto DTF film. This requires a DTF printer, which is specially designed to work with water-based pigment inks.

- Printer Settings: Set your printer to high resolution to ensure the design is printed accurately and with vibrant colors.

- Mirroring: Unlike other transfer methods, DTF does not require you to mirror your design before printing, which simplifies the process.

Apply Adhesive Powder

Once your design is printed onto the DTF film, the next step is to apply adhesive powder. This is essential, as it helps the ink adhere to the fabric during the transfer process.

- Sprinkle the Powder: While the ink is still wet, evenly sprinkle the adhesive powder across the printed design.

- Shake Off Excess: It’s important to shake off any excess powder to avoid uneven coverage or clumping.

Cure the Adhesive Powder

After applying the adhesive powder, the next step is curing it to ensure it bonds properly with the print. This step is essential to make sure that the transfer adheres well to the fabric.

- Heat Press or Oven: Cure the powder by applying heat, typically at 170°C (338°F) for 2-3 minutes. However, the exact time and temperature may vary depending on the type of powder used, so always refer to the manufacturer’s recommendations.

Heat Press the Transfer

Once your transfer is ready, it’s time to apply it to the fabric or material of your choice, such as t-shirts, bags, or hats.

- Preheat the Heat Press: Set the heat press to 160°C (320°F).

- Apply the Transfer: Place the printed side of the film onto the fabric and apply pressure for 15-20 seconds.

Always follow the heat press manufacturer’s guidelines for pressure and time to ensure proper adhesion. Using too much or too little pressure can negatively affect the quality of the transfer.

Peel the Film

After pressing, carefully peel off the film while it’s still warm. The design should remain on the fabric, leaving behind a clear and vibrant image.

Allow the fabric to cool down before handling it to ensure the transfer is fully bonded to the material.

Final Touches

To add extra durability to the transfer, press it again using a Teflon sheet or parchment paper. This step ensures that the transfer is more resistant to wear and washing.

Tips for Successful DTF Transfers

- Test Different Materials: While DTF works well on cotton, polyester, and fabric blends, it’s always a good idea to test the transfer on a small sample first before proceeding with larger batches.

- Use High-Quality Inks and Powder: High-quality inks and powder will ensure that the transfer lasts longer and maintains its vibrant colors.

- Care for DTF Prints: To preserve the transfer, wash garments inside out in cold water and air dry or tumble dry on low heat to extend the transfer’s lifespan.

Conclusion

DTF transfer printing is a versatile and efficient method for creating custom designs on various materials. By following these steps and using the right equipment and materials, you can easily create vibrant, high-quality transfers that stand the test of time. Whether you’re printing custom t-shirts for personal or business use, DTF provides excellent results with minimal hassle.

However, by following these simple steps and using high-quality materials, you will be able to produce long-lasting and professional-looking custom transfers.

More information

Check Out Our Other Products