What is DTF Powder

What is DTF Powder? Everything You Need to Know

If you’re exploring DTF printing (Direct-to-Film), you’ve probably heard about DTF powder. But what exactly is it, and why is it so important? In this guide, we’ll explain everything about Direct-to-Film powder, its role in the printing process, and how it ensures vibrant, durable designs.

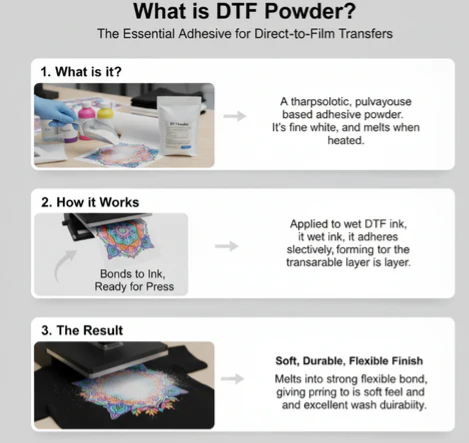

What is DTF Powder?

Direct-to-Film powder is a special adhesive powder used in the DTF printing process. After printing a design onto a PET film with DTF inks, this powder is applied over the wet ink. It helps the design stick to the fabric when heat-pressed.

Essentially, Direct-to-Film powder acts as a bonding agent between the printed design and the garment. Without it, the ink wouldn’t properly adhere, and the design would peel off after washing.

Types of Direct-to-Film Powder

There are different Direct-to-Film powders available depending on the fabric and desired finish:

-

Hot-Melt Powder: The most common type. It melts during heat pressing to securely bond the design to the fabric.

-

Frosted/Transparent Powder: Creates a smooth, invisible finish on light-colored fabrics.

-

Specialty Powders: Used for textured fabrics or to add extra effects like gloss or matte finishes.

Choosing the right powder is key to achieving durable and high-quality prints.

How Direct-to-Film Powder Works in the Printing Process

-

Print the Design → Use a DTF printer to print your design on the matte side of the PET film.

-

Apply the Powder → While the ink is still wet, sprinkle DTF powder evenly over the design. Shake off any excess.

-

Cure the Powder → Heat the film in a curing oven or under a heat press to melt the powder and bond it to the ink.

-

Transfer to Fabric → Press the film onto your garment using a heat press. The powder ensures a strong adhesion between the design and the fabric.

This simple but essential step makes all the difference in wash resistance and print quality.

Benefits of Using Direct-to-Film Powder

-

Strong Adhesion: Ensures that prints stick firmly to fabrics.

-

Durable Prints: Designs last through multiple washes without cracking or peeling.

-

Vibrant Colors: Helps maintain the bright colors of DTF inks.

-

Versatile: Works on cotton, polyester, and blended fabrics.

Without DTF powder, even a perfectly printed design would not transfer properly or last long on garments.

Tips for Using Direct-to-Film Powder

-

Even Application: Always make sure the layer is spread as evenly as possible. This prevents certain areas from becoming too thick or too thin, which can affect the look and durability of the transfer.

-

Shake Off Excess: After application, gently tap or shake off the extra. Leaving too much can cause clumps, uneven textures, or even reduce the flexibility of the finished design.

-

Cure Properly: Heat plays a vital role in bonding. Pay close attention to temperature and timing recommendations, as both under-curing and over-curing can affect the final result.

-

Store Carefully: Humidity and heat can damage the powder. Keep it sealed, in a cool and dry environment, so it stays fresh and performs consistently.

Following these simple yet important practices will help you achieve smooth, clean, and long-lasting results every single time.

Conclusion

Although it may appear to be a small step in the overall process, this material is what makes everything come together. It ensures that printed designs attach securely, remain flexible, and withstand daily use and washing without fading or peeling.

For those running businesses, this reliability means fewer returns, happier customers, and a reputation for quality. For hobbyists or creators working on personal projects, it’s the difference between a design that looks temporary and one that truly lasts.

Mastering the correct handling methods doesn’t require advanced technical knowledge—just a little care, patience, and consistency. Once you become comfortable with the process, you’ll find that it opens a wide range of creative opportunities, whether for clothing, accessories, or promotional products.

In the end, learning to use this essential component effectively is about more than just improving prints—it’s about unlocking new creative potential and achieving results that feel professional every time.

Check Out Our Other Products

More information