Let customers speak for us

DTF Prints Ready to Press: Quick, High-Quality Transfers for Apparel

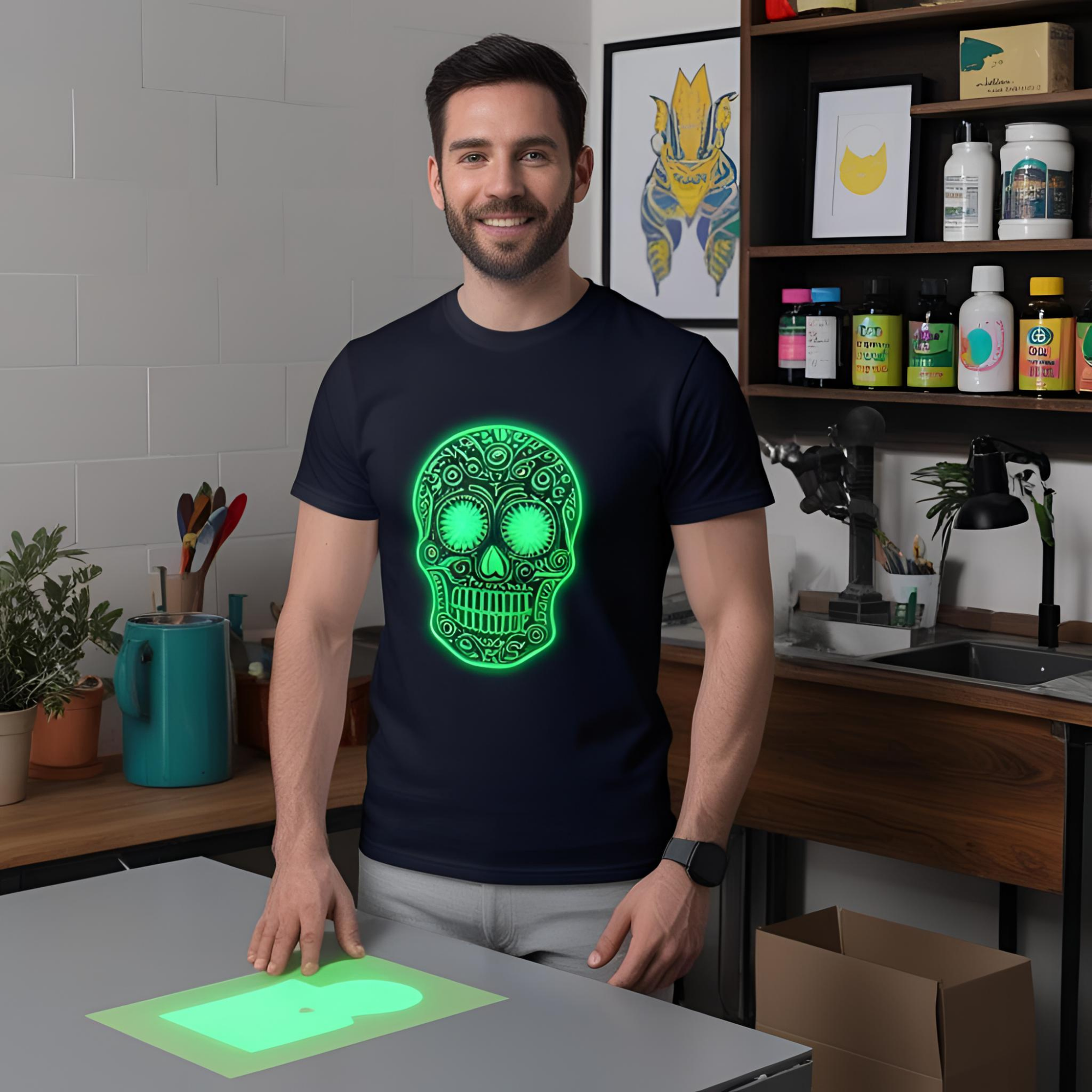

DTF (Direct-to-Film) printing has transformed the world of custom apparel. For designers, small business owners, and hobbyists, ready-to-press DTF prints offer a fast and reliable way to create vibrant, professional-quality garments. This category features pre-printed transfers that simplify the printing process, allowing you to focus on creativity without the complexity of preparing your own films and adhesives.

What Are Ready-to-Press DTF Prints?

Ready-to-press DTF prints are pre-made transfers printed on specialized PET film. Each transfer includes the design, adhesive coating, and curing, meaning the print is ready to be applied directly to fabric using a heat press. These transfers save time, reduce waste, and ensure consistent results, making them ideal for both beginners and experienced printers.

Advantages of Using Ready-to-Press Transfers

Time-Saving: Because the prints come pre-coated and cured, you can skip multiple steps in the traditional DTF process. This is especially useful for small businesses managing multiple orders or for hobbyists working on limited schedules.

Consistent Quality: Each transfer is professionally prepared to maintain color accuracy, detail, and durability. This eliminates the common issues of uneven adhesion or color fading often seen with homemade transfers.

Versatility: Ready-to-press DTF prints can be applied to a wide range of fabrics, including cotton, polyester, and blended materials. This flexibility allows you to create customized apparel for various occasions and purposes.

Ease of Use: Pre-made transfers simplify the process. All you need is a heat press, and your design is ready to transfer to your chosen fabric. Even beginners can achieve professional-looking results without extensive experience.

How to Apply Ready-to-Press DTF Prints

-

Prepare the Fabric: Ensure your fabric is clean and wrinkle-free.

-

Set the Heat Press: Adjust temperature and pressure according to the transfer instructions.

-

Place the Transfer: Position the pre-printed DTF film on the fabric.

-

Press the Design: Use the heat press to transfer the design from film to fabric.

-

Peel and Finish: Once the transfer has cooled, peel off the film and inspect the print.

Following these steps carefully ensures vibrant colors, sharp details, and long-lasting adhesion.

Tips for Best Results

-

Check Fabric Compatibility: Test on a small section if using a new fabric type.

-

Use Proper Heat Settings: Follow manufacturer recommendations for temperature and pressing time.

-

Store Transfers Correctly: Keep ready-to-press prints flat and away from moisture or direct sunlight.

-

Perform Routine Equipment Maintenance: Regularly clean your heat press to avoid uneven transfers.

Expand Your Creative Options

With pre-made transfers, your creative possibilities are nearly endless. You can produce custom t-shirts, hoodies, tote bags, and more. Layer designs, mix colors, or combine patterns to achieve unique effects.

Suppliers often offer a wide variety of designs, from simple logos to detailed illustrations. This makes it easy to find prints that match your style or brand. For small business owners, pre-made transfers allow you to produce multiple items quickly without investing in full printing equipment.

Why Choose Pre-Made Transfers

Pre-made transfers simplify the production process and save time. They provide consistent results and reduce the effort needed to create your own films and adhesives. This is especially helpful for small businesses, custom shops, or hobbyists looking for professional-quality results with minimal setup.

Using ready items lets you focus on creativity, variety, and quality instead of spending time on preparation. It also lowers the risk of mistakes and wasted materials, which is important for larger orders.

Conclusion

Pre-made transfers are an efficient, practical, and high-quality solution for creating custom apparel. They are ready to use, with adhesive already applied and cured, making the transfer process simple.

Whether you are trying personalized designs at home or producing bulk items professionally, pre-made transfers save time, ensure consistent quality, and expand your creative options. Using these transfers, you can bring your ideas to life with vibrant colors, sharp details, and durable results.