What is Gang Sheet

What is a Gang Sheet? A Guide to Optimizing Your Printing Workflow

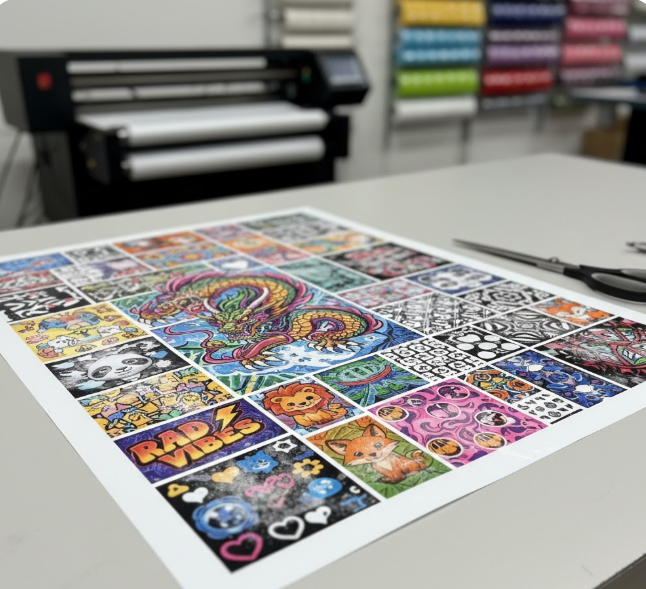

Efficiency holds immense importance in the digital textile printing world. The term Gang Sheet represents a core concept used to maximize this efficiency. Simply defined, this process involves arranging multiple designs—or several copies of the same design in various sizes—onto a single transfer film or paper. With the widespread adoption of DTF (Direct-to-Film) printing technology, Gang Sheet utilization has become an indispensable practice for print shops of all sizes, both large and small.

Origin and Purpose of the Gang Sheet Concept

The word "gang" has traditionally been used in the printing industry to mean "grouping" or "gathering together." This method has been actively used in the printing of newspapers, magazines, and general commercial printing for many years. Its objective has always remained the same: to minimize material waste and to reduce the cost per unit. In the context of DTF transfers, this process is an intelligent layout designed to utilize every square inch of expensive consumables like ink, film, and adhesive powder.

Creating a Gang Sheet means setting up the printing machine once and printing many different elements simultaneously. Instead of printing individual designs separately, all the jobs are consolidated onto a single long or wide roll. This consolidation of work yields significant savings in both time and money.

Core Benefits of Using Gang Sheets for Businesses

The advantages offered by DTF Gang Sheets extend far beyond merely cutting costs. This strategic approach fundamentally improves the workflow and provides a strong competitive edge:

1. Cost Efficiency and Material Conservation

Consumables represent one of the largest expenditure items for printing businesses. DTF films, in particular, are priced based on the square footage or linear meter. When you print just one small logo, a large portion of the film remains blank and is consequently wasted. By implementing Gang Sheets, you can fill these empty spaces with smaller logos from other orders, neck tags, or different designs. As a result, the material cost associated with each individual print is dramatically reduced. This practice maximizes profitability, especially for high-volume orders or jobs involving a wide variety of designs.

2. Time Savings and Increased Production Speed

Printing every design individually requires constantly stopping the machine and re-setting it up for a new print job. These interruptions invariably extend the total production time. However, submitting one long Gang Sheet as a single continuous print job allows the machine to run without interruption. This continuous flow enables you to complete bulk orders much more rapidly. Ultimately, this efficiency gain in printing time enhances your ability to meet tight delivery deadlines.

3. Flexibility in Design and Order Management

Gang Sheets provide an incredible degree of flexibility. You can simultaneously print both a large back design and ten small chest logos. Moreover, you can gather various sizes of the same design, required for different garment sizes, onto a single layout. This versatility simplifies the management of complex orders. For instance, you can arrange both team uniform numbers and small sponsor logos onto one single roll for a sports team.

4. Consistency in Quality

Printing all designs on a single roll with the same film and ink settings ensures perfect consistency in color and density. Every single design undergoes the exact same curing and powder application process. This uniform handling eliminates potential color variations or quality fluctuations that might otherwise occur between separate print runs. It guarantees that you consistently deliver the same high-quality product to your customers.

How to Prepare an Effective Gang Sheets

The creation of a Gang Sheet is often considered an art form. Your goal is to use the space most efficiently while leaving sufficient room for cutting between the designs (typically about 0.5 cm or 0.2 inches).

-

Design Preparation: Prepare all your designs in high-resolution (300 DPI) format, such as PNG or TIFF, with a transparent background. Image quality is crucial because the final print directly mirrors the quality of the submitted file.

-

Optimization Software: Most professional suppliers utilize automated software, known as nesting programs, to arrange the designs onto the film. These programs intelligently position different shapes closer together, filling in any awkward blank spaces.

-

Cutting Space: Avoid placing designs too close to each other. A small border (the white adhesive outline) must be left around each transfer so it can be easily cut. This prevents the ink transfer from accidentally bleeding onto other designs during application.

-

Pricing Model: Most services price a Gang Sheet not by the number of individual transfers printed, but by the length or square area of the film used. Consequently, the more designs you pack onto your film, the lower your cost per unit becomes.

The Post-Application Process for Gang Sheets

The process isn't over once a large Gang Sheet has been successfully printed. The transfer film must be cured and allowed to cool completely. Following this, the operator or end-user carefully separates each individual design using scissors or a cutting plotter. These individual pieces are then ready to be transferred separately onto garments using a heat press machine.

In conclusion, the Gang Sheets is essentially the foundation of DTF printing. This technique is a mandatory practice for any business aiming to control costs, increase delivery speed, and maintain consistency in print quality. With correct planning and arrangement, you can turn every inch of your printing roll into profit.