How to Make a DTF Transfer

A Comprehensive Industry Guide DTF Transfer

The apparel industry is undergoing a digital revolution. More businesses are moving toward Direct-to-Film technology every day. Learning How to Make a DTF Transfer allows you to create high-quality, custom apparel with ease. This method is preferred because it works on almost any fabric type. You can print on cotton, polyester, blends, and even nylon. Unlike traditional screen printing, there is no need for screens or messy cleanups. This guide provides a detailed look at the production process. We will cover everything from digital design to the final curing stage.

The Fundamental Concepts of DTF

Before you start production, you must understand the core mechanics. A DTF transfer consists of three main components: ink, film, and adhesive.

The Specialty Ink System DTF uses a specific type of water-based pigment ink. These inks are formulated to be flexible and highly opaque. When you learn How to Make a DTF Transfer, you will see that white ink is vital. It provides the base layer that makes colors stand out on dark shirts. Without a strong white backing, the colors would look dull and transparent.

The Role of the PET Film The film acts as a temporary carrier for your design. It has a special coating that holds the wet ink without letting it smudge. High-quality film ensures that the ink stays in place until the adhesive is applied. The film is usually transparent, making it easy to align the design on the garment later.

Essential Equipment for Production

To produce professional transfers, you need the right tools. Standard inkjet printers will not work for this process.

-

Converted DTF Printer: A printer equipped with a white ink circulation system.

-

RIP Software: Specialized software to control ink layers and color profiles.

-

DTF Inks: High-pigment CMYK and White textile inks.

-

Adhesive Powder: TPU hot-melt powder for bonding.

-

Curing Oven or Heat Press: Used to melt the powder into the ink.

Step 1: Designing and Software Setup

Everything begins on your computer screen. This is the first critical step in How to Make a DTF Transfer.

Creating Your Artwork Use professional design software to create your graphics. High-resolution PNG files with transparent backgrounds are the industry standard. Ensure your design is at least 300 DPI for the best clarity. Any low-resolution images will look blurry when printed on a large scale.

Configuring the RIP Software You cannot print a DTF transfer through a normal print driver. You must use RIP (Raster Image Processor) software. This software allows you to mirror your image automatically. It also creates the white ink mask that sits behind the colors. Proper software settings prevent the ink from "pooling" or running off the film.

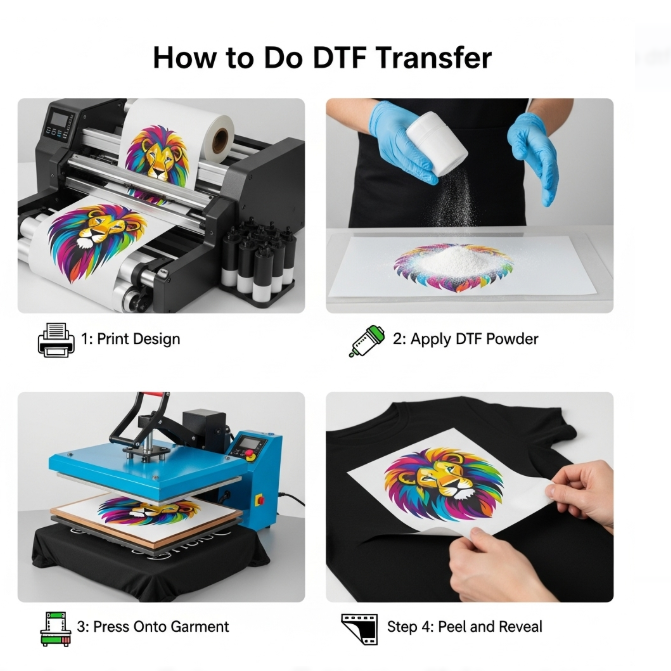

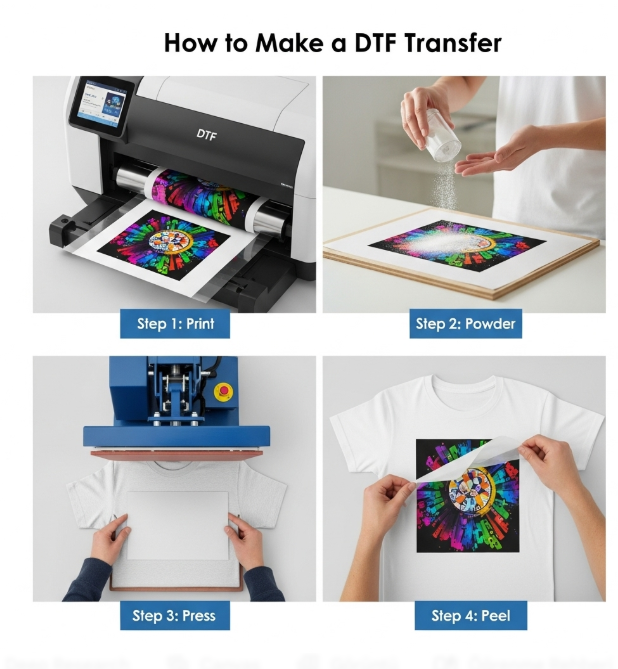

Step 2: The Printing Process

Once your file is ready, you can start the physical printing phase.

Loading the Film Identify the "matte" side of your PET film. This is the side with the chemical coating. Always print on the matte side for proper ink adhesion. If you print on the glossy side, the ink will not dry or stick.

Printing the Layers The printer will first apply the color pigments (CMYK). Immediately after, it prints a solid layer of white ink over the colors. In the world of How to Make a DTF Transfer, this is called "under-basing." The white ink must remain wet and tacky for the next stage of the process.

Step 3: Applying the Adhesive Powder

This is the "glue" that makes the transfer permanent. It must be applied while the ink is still fresh.

Covering the Design Spread the DTF Printing Powder evenly over the wet white ink. You can do this by hand in a tray or with an automated shaker machine. Make sure every printed area is fully covered by the white dust.

Removing Excess Powder Flick or shake the film to remove any loose powder from the unprinted areas. Only the wet ink should hold onto the powder. If extra powder stays on the clear film, it will leave small white dots on your shirt. A clean transfer is a mark of professional quality. To achieve the best results, you should use high-quality materials. You can explore the

Step 4: Curing the Transfer

The adhesive powder must be melted to become an effective glue. This is called the "curing" process.

Using a Curing Oven Place the powdered film inside a DTF curing oven. Most professionals cure at 150°C (302°F) for about 2 minutes. The powder should melt until it looks smooth and slightly shiny. Do not over-bake the film, or it may become brittle.

The Hovering Method If you don't have an oven, you can use a heat press. Hover the heat platen about 1 inch above the film. The heat from the press will melt the powder without touching it. This is a common method for those just learning How to Make a DTF Transfer at home.

Step 5: Testing and Quality Control

Before you press your transfer onto an expensive garment, you must check its quality.

The Scratch Test Once the transfer has cooled, gently rub your finger over the cured ink. The powder should be fully integrated into the ink. It should not feel grainy or like loose sand. If it feels sandy, you need more heat or more time in the oven.

Storage and Longevity Cured transfers can be stored for months. Keep them in a cool, dry place inside a sealed bag. This allows you to print designs in advance and use them whenever you receive an order. It is an excellent way to scale your business.

Common Challenges in DTF Production

Even experts face hurdles when learning How to Make a DTF Transfer.

-

Ink Clogging: White ink settles very quickly. You must shake your tanks daily to keep the ink flowing.

-

Humidity Issues: If the air is too humid, the powder may clump. Try to keep your workspace between 40% and 60% humidity.

-

Oily Residue: If the film looks oily after curing, it usually means the oven temperature was too low or the ink was too thick.

Conclusion

Mastering the art of How to Make a DTF Transfer takes time and practice. By following these steps, you can create durable and vibrant apparel for any customer. Focus on using high-quality inks, films, and powders for the best results. Always maintain your equipment to avoid downtime. With the right setup, you can produce professional-grade transfers that rival any major retail brand.

Join our growing community online to stay updated with the latest trends and innovations in the printing world. Follow us on

V DTF technology allows you to achieve professional results not only on textiles but also on hard surfaces. To apply high-quality designs to items like tumblers, glass, metal, or plastic, the most efficient method is using the