DTF Printing Process

The Complete Guide to the DTF Printing Process

Direct-to-Film (DTF) printing has quickly become one of the most exciting and innovative methods in the custom apparel and printing industry. Unlike traditional techniques such as screen printing or heat transfer vinyl, the DTF printing process offers unmatched flexibility, vibrant colors, and long-lasting results. Whether you are a beginner or an experienced printer, understanding this process step by step will help you achieve professional-quality prints every time.

What is the DTF Printing Process?

The DTF printing process is a technique where designs are printed directly onto a special PET film using high-quality DTF inks. After printing, the design is coated with adhesive powder, cured, and finally transferred onto fabric or other surfaces using a heat press.

This method is gaining popularity because it allows printing on almost any material, from cotton and polyester to blends, leather, and even wood. Unlike sublimation, which is limited to light polyester, DTF printing provides true versatility.

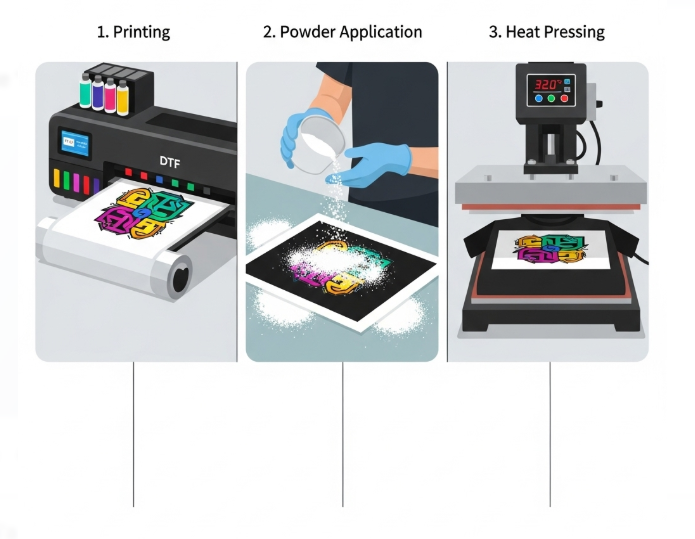

Step-by-Step Breakdown of the DTF Printing Process

1. Artwork Preparation

The first step in the process is creating or preparing your artwork. Designers typically use software such as Adobe Illustrator, Photoshop, or CorelDRAW. It is important to ensure that the file has a transparent background. Using CMYK color mode helps achieve accurate color reproduction. High-resolution files produce sharper and more detailed prints. Simple, bold designs often perform better, but intricate patterns can also work well when properly prepared. Before moving to the printing stage, reviewing the artwork for errors or unnecessary layers is recommended. A well-prepared file reduces the chances of mistakes in the following steps and ensures a smoother production process.

2. Printing on PET Film

After the artwork is ready, it is printed onto a PET transfer film. This requires a specialized printer and pigment-based inks. These inks are designed to produce vibrant, long-lasting colors that remain sharp after multiple washes. The film acts as the medium that will transfer the design to the fabric. It is essential to print the design in mirror mode, especially for text or directional images. Careful handling of the printed film is necessary to prevent smudges or dust contamination. At this stage, attention to detail ensures that the final print on the fabric will be clean and precise.

3. Applying Adhesive Powder

While the ink on the film is still wet, a fine adhesive powder is applied. This powder helps the ink bond strongly to the fabric during heat pressing. Excess powder is removed to prevent clumping or uneven transfer. Applying the powder evenly ensures the design adheres correctly and produces a consistent finish. Working in a clean, dust-free environment helps maintain the quality of the print. This step is crucial because improper application can cause peeling or weak spots on the final product. Proper technique and precision here directly impact the durability of the transferred design.

4. Curing the Film

Next, the film must be cured. This involves heating it in a curing oven or using a heat press. The heat melts the adhesive powder, bonding it with the ink. Proper curing is critical to prevent issues such as peeling or fading after transfer. Under-curing may lead to weak adhesion, while over-curing can damage colors and reduce print quality. Temperature and timing need to be carefully monitored. Curing prepares the film so it is ready for the heat press stage. Consistency during this step ensures that each print is uniform, even when producing multiple items in one batch.

5. Heat Press Transfer

Once the film is cured, it is placed on the fabric and pressed using a heat press. The combination of heat and pressure transfers the design from the film to the garment. Applying the right pressure and temperature ensures the ink and adhesive bond properly to the material. Each type of fabric may require different heat settings to avoid scorching or uneven transfer. After pressing, the garment is inspected to ensure the design is fully adhered and free from defects. This step finalizes the print and guarantees a professional-quality result.

6. Final Touch – Cold Peel

After pressing, the film is allowed to cool before peeling it away. This cold peel method reveals the finished design. Cooling helps the adhesive set fully and prevents the design from lifting or smudging. The final result is a smooth, vibrant print that can withstand regular washing and daily wear. At this stage, minor adjustments can be made if needed, such as pressing from the back of the fabric for extra durability. Proper handling ensures the garment looks clean and polished, ready for use or sale.

Benefits of the Process

This printing method offers several advantages.

-

Versatility: It works on a wide range of fabrics, including cotton, polyester, blends, and canvas.

-

Durability: Prints are resistant to stretching, washing, and daily wear.

-

Cost-Effectiveness: Suitable for both small batches and large-scale production without requiring expensive setups.

-

Color Accuracy: The process produces sharp, detailed designs with vibrant colors.

-

No Pre-Treatment Needed: Unlike some other printing techniques, fabrics do not require pre-treatment.

The method allows for creative freedom while maintaining high quality and reliability. It can be used for custom apparel, promotional products, or small personal projects.

Final Thoughts - DTF Printing Process

This DTF Printing Process has significantly changed how custom garments are produced. It allows creators and businesses to make long-lasting, vibrant designs on almost any fabric. From individual items to bulk production, it delivers consistent results. The method is flexible, efficient, and cost-effective. It reduces the need for complex equipment and saves time compared to traditional printing methods.

As technology continues to improve, this process becomes faster, more precise, and easier to use. It opens opportunities for small entrepreneurs and large companies alike. Creative individuals can experiment with colors and designs without worrying about limitations. The process also ensures durability, allowing garments to be worn and washed without losing quality.

Overall, this method is not just a trend. It represents the future of custom apparel production. Its versatility, efficiency, and quality make it suitable for a wide range of applications. Businesses and hobbyists alike can benefit from adopting it. By understanding and following each step carefully, anyone can achieve professional results that last.