Let customers speak for us

Gang Sheet DTF Transfers – Efficient and High-Quality Printing

Gang sheet DTF transfers are a popular choice for businesses, designers, and custom apparel makers who want to maximize efficiency while maintaining high-quality prints. These transfers allow multiple designs to be printed together on a single sheet, reducing production time, material waste, and cost. They are ideal for bulk orders, promotional merchandise, and custom clothing projects where consistency and detail are important.

What Are Gang Sheet DTF Transfers?

Gang sheet DTF transfers are large-format transfer sheets that hold multiple designs in a single layout. Instead of printing each design separately, you can print several items at once, saving time and effort. These sheets are made using high-quality PET film coated with a heat-sensitive adhesive powder, which allows designs to transfer cleanly onto fabric after heat pressing.

The technology behind DTF (Direct-to-Film) ensures that designs are reproduced with vibrant colors and precise details. This process is suitable for both simple graphics and complex, high-resolution images. Gang sheet DTF transfers allow businesses to maintain consistency across multiple products while reducing the chance of errors during the printing process.

Advantages of Gang Sheet DTF Transfers

One of the primary advantages is efficiency. Printing multiple designs on a single sheet allows for faster production. For businesses handling large orders, this can significantly reduce labor time and speed up the delivery process. This efficiency is especially important in industries where quick turnaround times are crucial.

Another advantage is cost savings. Using gang sheets reduces the amount of transfer material required per design and minimizes wasted film. Bulk production with gang sheets lowers the overall cost per item, making it a practical choice for businesses aiming to maximize profit margins.

High-Quality Prints

Gang sheet DTF transfers deliver professional-quality results. The DTF printing process uses high-quality inks that produce vibrant colors, sharp edges, and fine details. Every design, whether it includes logos, text, or intricate artwork, comes out crisp and clear. The adhesive powder ensures the design adheres smoothly to the fabric, creating a durable and visually appealing print.

These transfers are compatible with a variety of fabrics, including cotton, polyester, blends, and specialty textiles. This flexibility allows brands to expand their product range while maintaining consistent quality across different materials.

Durability and Longevity

Durability is a key benefit of gang sheet DTF transfers. Prints are resistant to cracking, peeling, and fading, even after multiple washes. This long-lasting performance ensures that apparel, promotional items, and merchandise retain their vibrant appearance over time. For businesses, durability translates into satisfied customers and repeat orders, which strengthens brand reputation.

Ease of Use

Gang sheet DTF transfers are designed for a smooth application process. The pre-coated adhesive film allows for easy handling and alignment during heat pressing. The release film peels off cleanly after pressing, leaving a flawless finish on the fabric. This ease of use reduces production errors and allows even small businesses or new users to achieve professional results consistently.

Versatility Across Applications

These transfers are suitable for various applications, including custom t-shirts, hoodies, tote bags, hats, and other apparel items. They can also be used for promotional products, branded merchandise, and gifts. The versatility of gang sheet DTF transfers allows businesses to cater to different markets and client needs efficiently.

Cost-Effective for Bulk Orders

Gang sheet DTF transfers are particularly advantageous for bulk orders. By printing multiple designs on one sheet, businesses reduce production costs and speed up workflow. This makes it easier to fulfill large orders while maintaining consistent quality across all products. Bulk options also help small businesses grow by allowing them to compete with larger production facilities.

Customization Options

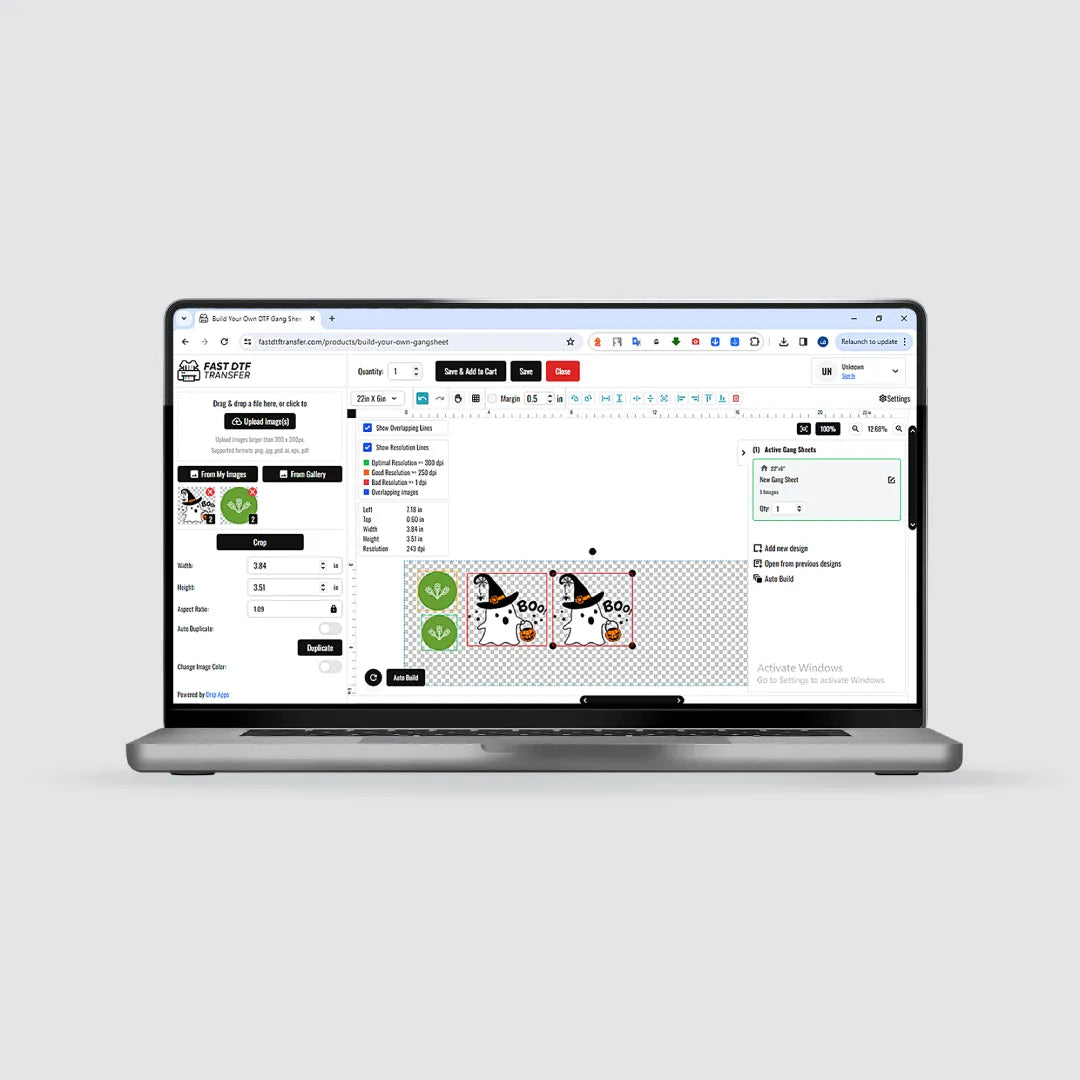

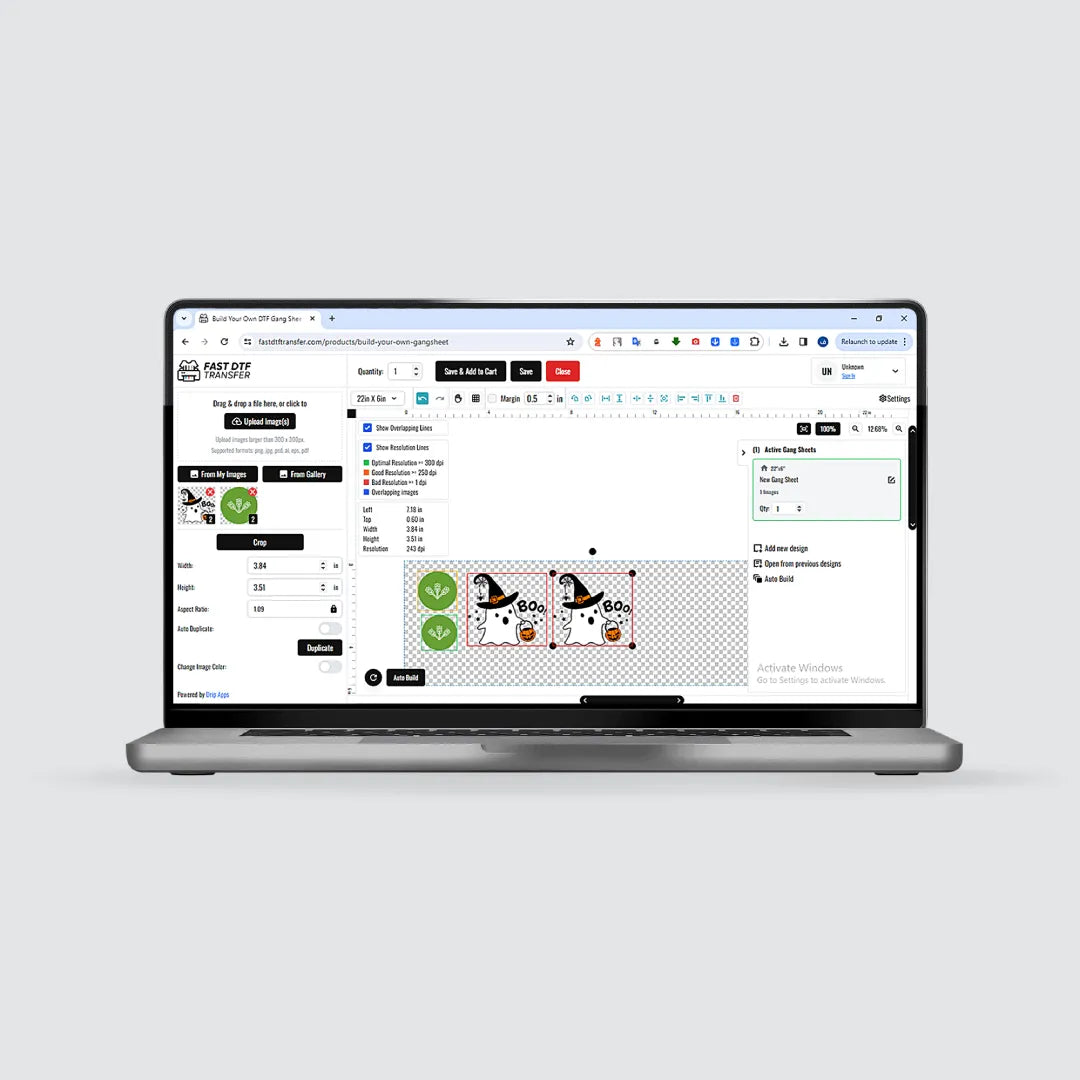

Gang sheet DTF transfers support a wide range of customization. Businesses can adjust design sizes, shapes, and layouts on a single sheet, allowing multiple unique products to be produced simultaneously. Custom colors, logos, and patterns can be integrated into the design, providing a flexible solution for personalized orders and branding projects.

Professional Branding

Using gang sheet DTF transfers ensures a professional look for all printed items. The high-quality finish and vibrant colors help brands stand out in the market. For promotional products, custom apparel, or corporate giveaways, gang sheets provide consistent, eye-catching results that enhance brand perception.

Workflow Efficiency

These transfers improve production workflow by minimizing setup and alignment time. Printing multiple designs on a single sheet reduces the risk of errors and ensures consistency across items. Businesses benefit from streamlined operations, faster order fulfillment, and reduced material waste, making the printing process more sustainable and efficient.

Sustainability Considerations

Many manufacturers of DTF gang sheets use environmentally conscious materials and processes. Reducing wasted film and minimizing reprints helps lower the overall environmental impact of production. Businesses that adopt gang sheet DTF transfers can achieve professional results while maintaining a commitment to sustainability.

Why Choose Gang Sheet DTF Transfers?

Gang sheet DTF transfers offer efficiency, cost-effectiveness, durability, and versatility. They are perfect for businesses seeking high-quality, consistent results on bulk orders. The combination of vibrant colors, long-lasting adhesion, and professional finish makes these transfers a reliable choice for apparel brands, promotional product makers, and creative designers.

Conclusion

Gang sheet DTF transfers are a smart solution for businesses and creators looking to produce high-quality prints efficiently. They combine vibrant colors, precise detail, and long-lasting durability with the ability to print multiple designs at once. Suitable for various fabrics and products, gang sheets reduce production time, minimize material waste, and provide consistent professional results. By using gang sheet DTF transfers, businesses can meet high-volume orders, maintain brand consistency, and deliver appealing, durable products that satisfy customers.

More information

Please Click to get DTF INK

Please Click to get Custom Printing - Gang Sheet