Let customers speak for us

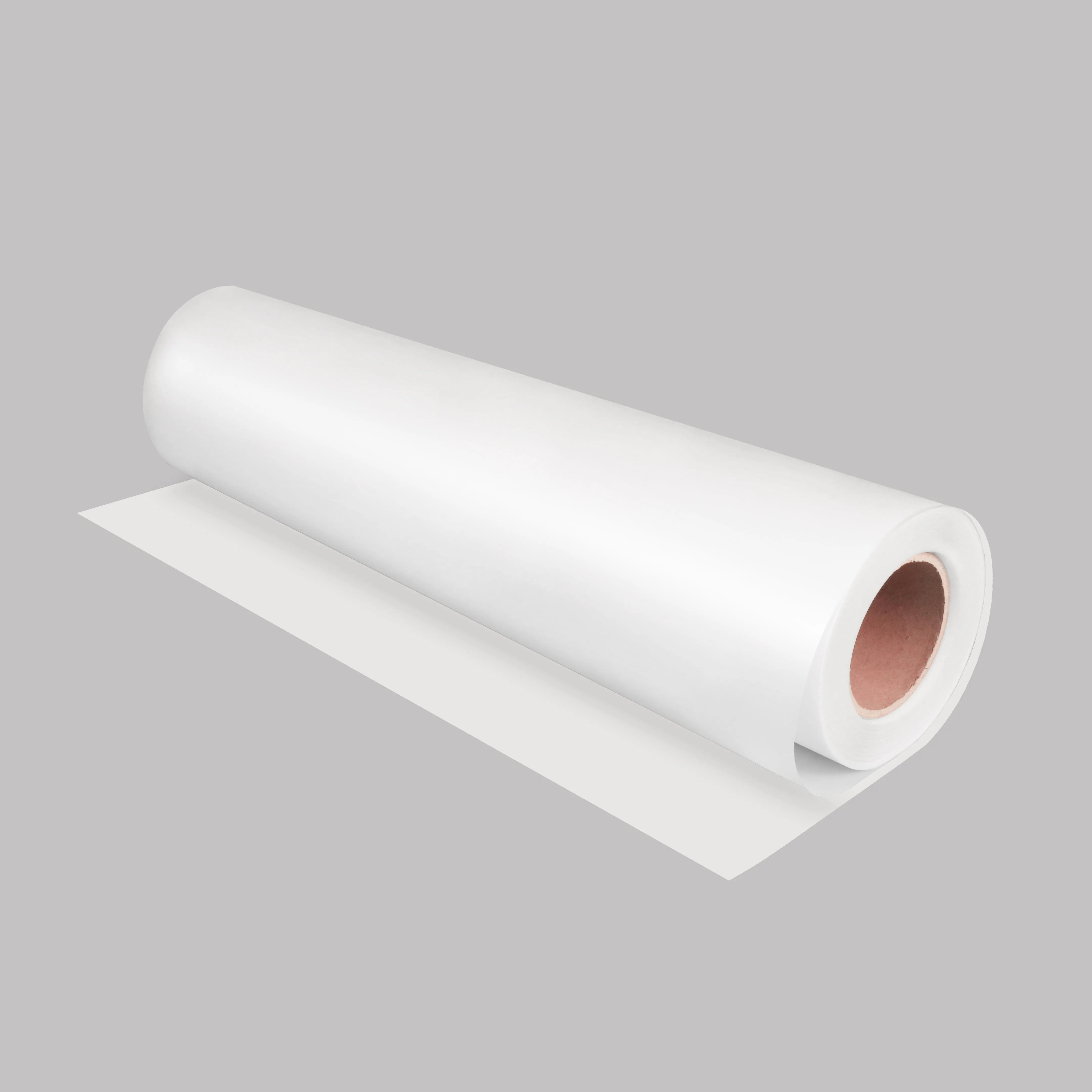

DTF Film Roll: High-Quality Printing for Professional Results

In the world of textile and apparel printing, DTF film roll has become an essential product for both small businesses and large-scale manufacturers. Its ability to deliver vibrant, detailed, and durable designs has made it a preferred choice for custom printing. Whether you are producing t-shirts, hoodies, tote bags, or promotional items, a reliable film roll ensures consistency, efficiency, and professional-quality results.

What is a DTF Film Roll?

A DTF film roll is a specialized transfer film designed for Direct-to-Film printing. Instead of using cut vinyl or traditional screen printing methods, this film allows high-resolution designs to be printed directly onto the film with DTF inks. After printing, the design is coated with adhesive powder, cured, and then transferred onto fabric using a heat press.

Film rolls are available in different widths and lengths, making them suitable for both desktop DTF printers and industrial machines. This flexibility makes them ideal for businesses of all sizes.

Benefits of Using DTF Film Rolls

There are several reasons why DTF film rolls are considered the backbone of modern custom printing:

-

Sharp Print Quality: Capable of producing high-definition images with fine details and vibrant colors.

-

Durability: Transfers remain bright and flexible after many washes, resisting cracks or peeling.

-

Versatility: Works on cotton, polyester, blends, and dark fabrics.

-

Efficiency: Roll format allows for continuous printing, saving time and reducing waste.

-

Cost-Effective: Lowers production costs while maintaining premium quality.

How DTF Film Rolls Work

The process of using a film roll is straightforward:

-

Print: The design is printed onto the film using DTF inks.

-

Apply Powder: A special adhesive powder is applied to the wet ink.

-

Cure: The powder is melted onto the design with heat, preparing it for transfer.

-

Press: Using a heat press, the design is transferred from the film to the fabric.

-

Peel: Once cooled, the film is peeled away, leaving a vibrant, long-lasting design.

This process makes DTF technology simple, reliable, and highly adaptable.

Why Choose Film Rolls Over Sheets?

While sheets are practical for small projects, rolls provide greater efficiency for professional use. Rolls enable continuous printing, which is especially valuable for bulk orders. They reduce downtime, minimize material waste, and improve overall workflow.

Ideal for Small and Large Businesses

DTF film rolls are perfect for startups as well as established businesses. Small companies can benefit from the affordability and flexibility, while larger enterprises appreciate the consistency and scalability. With rolls, it’s possible to handle both small custom orders and large production runs without sacrificing quality.

Creative Applications

Film rolls can be used for a wide variety of creative projects:

-

Fashion Brands: Create detailed, multi-color prints for clothing collections.

-

Promotional Products: Add company logos to bags, caps, and uniforms.

-

Personalized Gifts: Print unique designs for birthdays, weddings, or holidays.

-

Team Apparel: Apply logos and names to jerseys and sportswear.

This versatility makes DTF film rolls a must-have for any printing operation.

Durability and Customer Satisfaction

One of the standout features of film rolls is their durability. Designs applied with this method can withstand frequent washing without fading or cracking. This reliability ensures higher customer satisfaction and helps businesses build a strong reputation for quality.

Eco-Friendly Printing

Compared to traditional printing techniques, DTF technology with film rolls is more eco-friendly. It reduces water consumption, eliminates the need for chemical pretreatments, and minimizes waste. This makes it an excellent option for businesses looking to adopt sustainable practices.

Choosing the Right Film Roll

When selecting a film roll, consider factors such as:

-

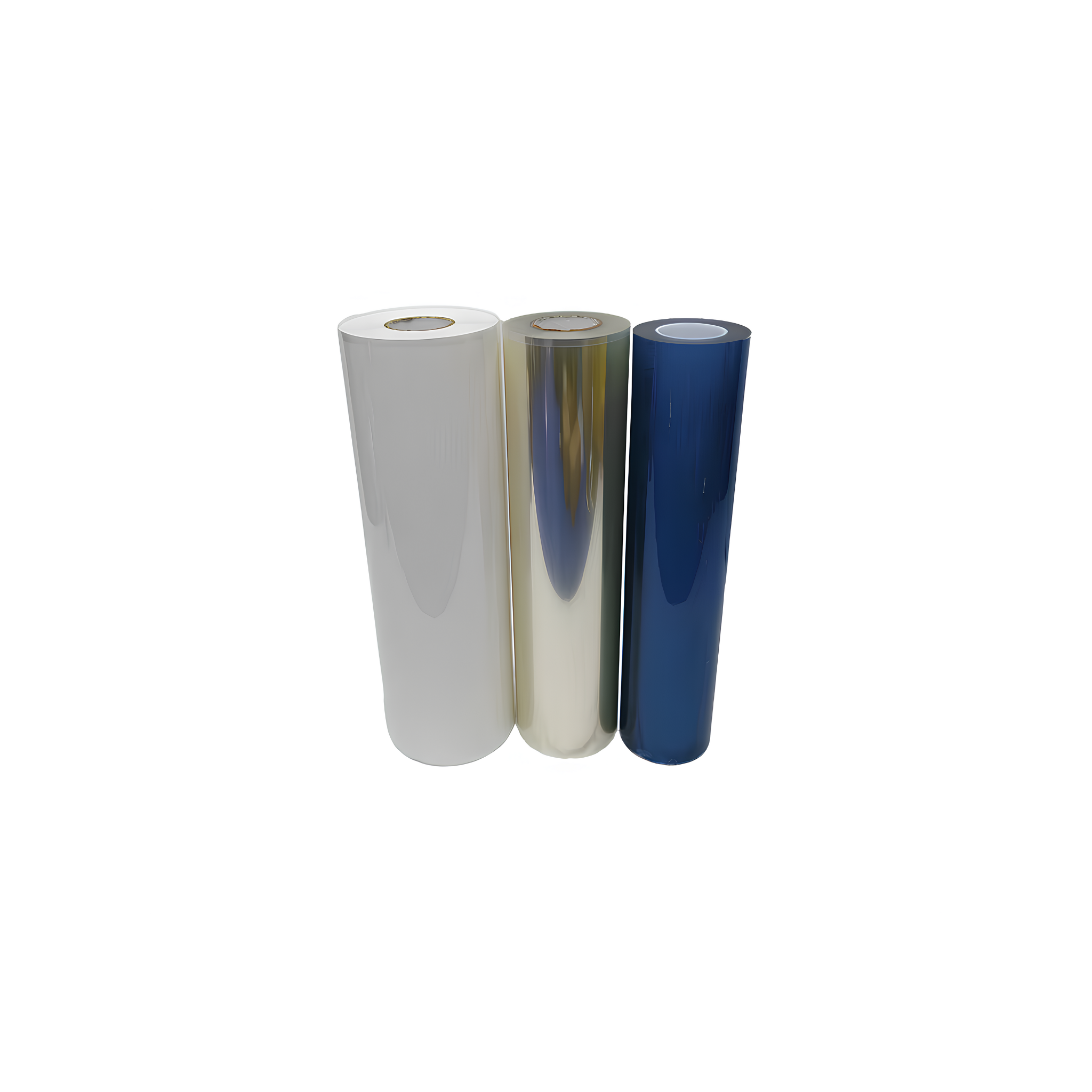

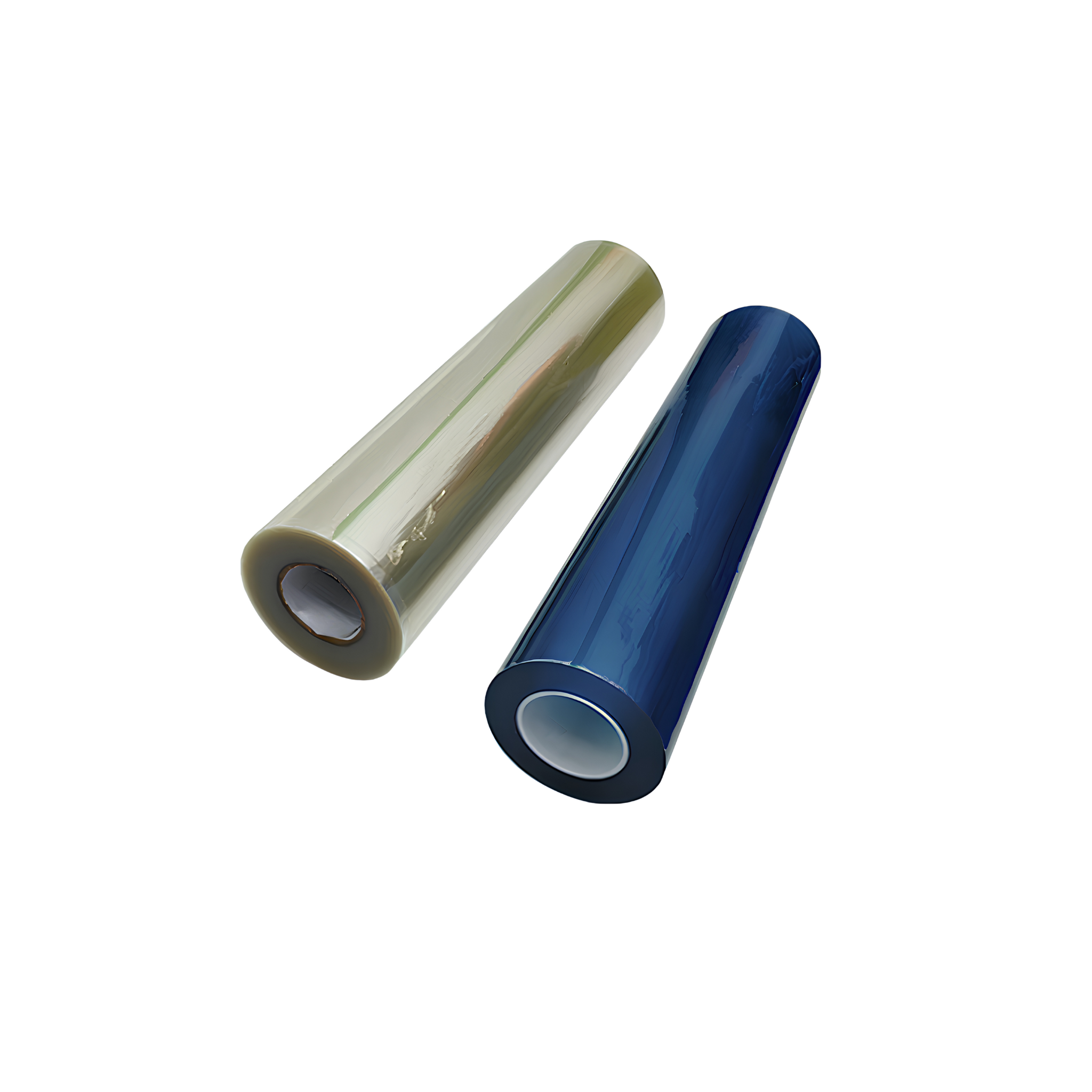

Coating Type: Hot peel vs. cold peel, depending on your workflow preference.

-

Thickness: Ensures durability and easy handling.

-

Printer Compatibility: Make sure the roll matches the specifications of your printer.

-

Finish: Glossy or matte finishes depending on the final look you want to achieve.

Buying from a trusted supplier guarantees consistent quality and reduces the risk of production issues.

Tips for Best Results

To achieve professional-quality transfers, follow these tips:

-

Store rolls in a cool, dry environment.

-

Avoid exposing the film to dust or moisture.

-

Always use recommended temperature and pressure settings.

-

Test your setup with small prints before starting bulk production.

Conclusion

DTF film roll technology has revolutionized custom apparel printing by offering vibrant, durable, and cost-effective results. Its ability to handle small or large projects with the same efficiency makes it a valuable tool for businesses of all sizes. From fashion lines and promotional products to personalized gifts and sportswear, film rolls provide endless creative opportunities.

Check Out Our Other Products

Please Click to get DTF Ink

More information