Let customers speak for us

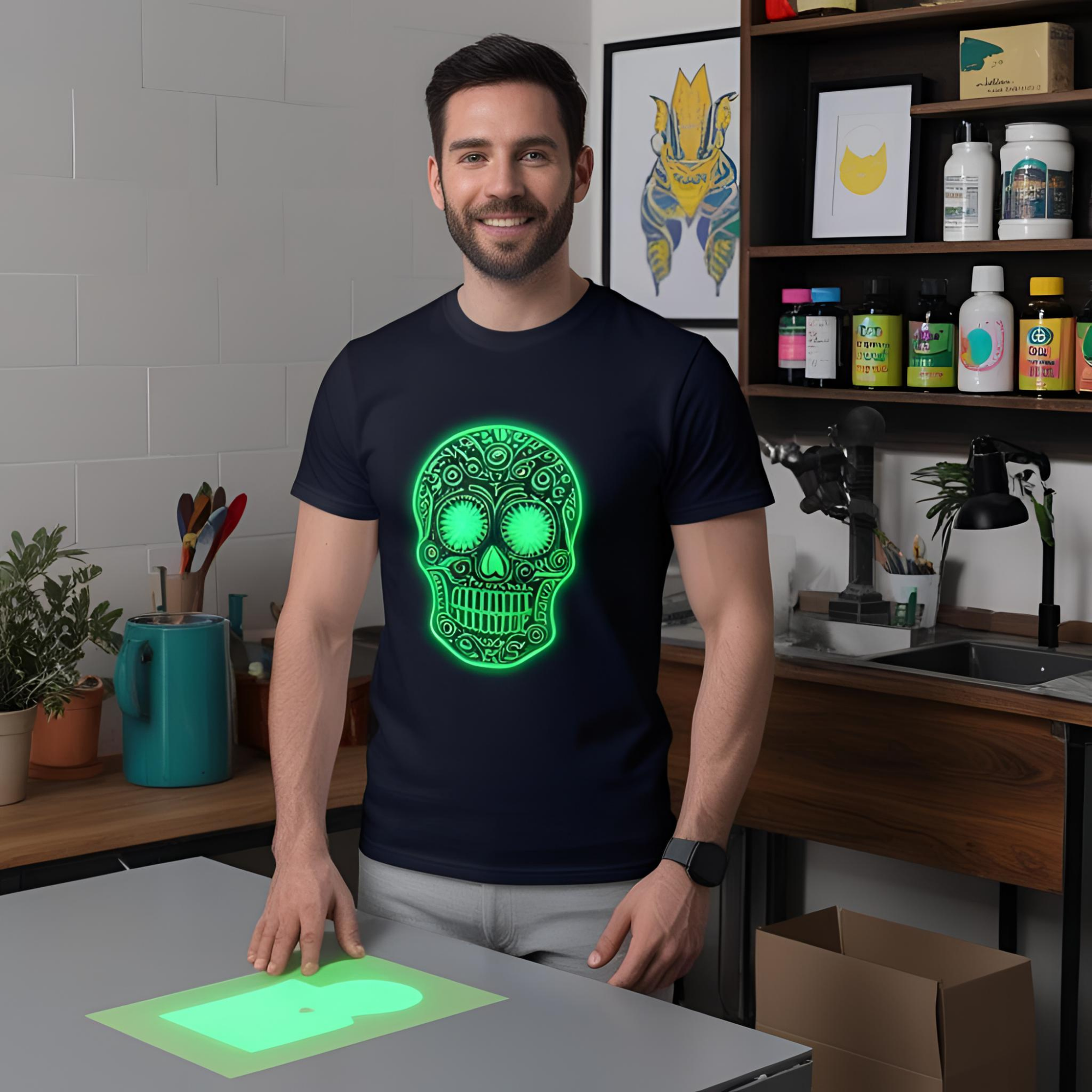

Direct Film Transfer – Professional Custom Printing

What is Direct Film Transfer?

Direct Film Transfer is a modern printing technique that allows designs to be applied directly onto fabrics.

It provides clear, vibrant, and long-lasting results for clothing, accessories, and promotional items.

This method is ideal for individuals, small businesses, and professional designers who want reliable and consistent quality.

How the Process Works

The process starts with a digital design that is printed onto a special transfer film using high-quality inks.

The film is then aligned with the fabric and heat and pressure are applied to transfer the design permanently.

This method ensures the design adheres well and maintains its color, detail, and durability.

Benefits of Direct Film Transfer

Direct Film Transfer reproduces detailed graphics, logos, text, and images accurately.

It is faster and more efficient than traditional screen printing, reducing setup time and errors.

The technique is cost-effective and works for both small orders and bulk production.

On-demand printing reduces waste and inventory needs, saving time and resources.

Compatible Materials

This method works on cotton, polyester, blends, and some synthetic fabrics.

It is effective on both light and dark textiles, giving designers flexibility in color and style.

The thin transfer film keeps garments soft and comfortable while maintaining professional-quality visuals.

Durability and Quality

Designs applied using this method are resistant to fading, peeling, or cracking.

Following recommended care instructions ensures long-lasting results.

This makes it suitable for everyday wear, corporate merchandise, gifts, and promotional products.

Customization Possibilities

Users can apply logos, typography, artwork, or photographic images to their products.

Seasonal collections, corporate gifts, and personal items can all be created with consistent quality.

This flexibility supports small businesses, online stores, and hobbyists who want unique, professional results.

Environmental Considerations

The inks and films meet safety and environmental standards.

Digital printing generates minimal waste compared to traditional methods.

Accuracy in printing reduces mistakes and material usage, supporting sustainable production.

Applications and Use Cases

Direct Film Transfer is suitable for t-shirts, hoodies, sweatshirts, hats, tote bags, and more.

It is used for branded merchandise, promotional products, uniforms, and personalized gifts.

Both single-item personalization and bulk production are easily handled with this method.

Visual and Functional Benefits

Products retain vibrant colors, clear details, and professional appearance.

Fine details and multi-color designs are reproduced accurately.

Garments remain soft and comfortable without added bulk.

Efficiency and Cost-Effectiveness

Compared to traditional screen printing, this method requires significantly less labor and setup, making it an ideal solution for both small businesses and large-scale production. The digital-based process eliminates the need for multiple screens, stencils, or complicated preparation steps, which reduces setup time and minimizes the chance of errors during production. This efficiency allows creators to focus more on design quality and customer satisfaction rather than spending hours on preparation.

DTF Transfer also supports fast turnaround times, enabling businesses to fulfill orders quickly and efficiently. On-demand production is possible, allowing for immediate response to customer requests without the need for large inventory storage. This flexibility not only improves workflow but also reduces storage costs and the risk of overproduction, which is particularly beneficial for seasonal items, limited editions, or custom orders.

From a financial perspective, the method is highly cost-effective. Reduced labor, minimized material waste, and the elimination of additional setup expenses contribute to lower production costs. Businesses can produce high-quality products without incurring the overhead associated with traditional printing methods. This makes it a practical choice for small enterprises, startups, or individual designers looking to deliver premium custom items while maintaining a profitable margin.

Additionally, the precision and consistency of this process ensure fewer defective products, further reducing waste and increasing overall efficiency. By streamlining production, minimizing errors, and optimizing material use, DTF Transfer allows businesses to maximize resources and provide clients with professional, high-quality results. Overall, this method combines speed, cost-efficiency, and reliability, offering a modern solution that meets the demands of contemporary custom printing needs.

Conclusion

DTF Transfer combines durability, versatility, and high-quality results in a single, reliable printing solution. Its advanced process ensures that each design adheres securely to the fabric, producing vibrant colors and sharp details that last over time. This method is compatible with a wide range of materials, including cotton, polyester, blends, and certain synthetic fabrics, which allows for creative flexibility without compromising comfort or wearability.

One of the most significant advantages of this technique is its ability to maintain garment softness and flexibility. Unlike some printing methods that can leave a heavy or stiff texture on the fabric, DTF Transfer preserves the natural feel of the garment while delivering professional-grade visuals. This combination of durability and comfort makes it ideal for everyday apparel, promotional items, corporate merchandise, and personalized gifts.