Let customers speak for us

Best DTF Film – Superior Quality for Perfect Transfers

In the world of garment decoration and digital printing, choosing the best DTF film can make a significant difference in print quality, durability, and overall production efficiency. Designed for Direct to Film (DTF) printing, this film ensures smooth ink transfer, strong adhesion, and long-lasting results on a variety of fabrics. Whether you are a professional print shop or a creative individual producing custom apparel, high-quality DTF film guarantees that every design looks vibrant and professional.

What Makes the Best DTF Film Stand Out

The best DTF films is engineered with advanced coating technology that allows even ink distribution and quick drying. Its anti-static surface prevents smudging, while the strong release layer ensures easy peeling after heat pressing. This combination helps achieve consistent results, even in high-volume production environments.

Unlike ordinary films, premium DTF films provides a clean transfer with no residue. The adhesive layer bonds firmly to the garment, maintaining the color vibrancy and detail of the design even after multiple washes. This makes it perfect for both light and dark fabrics, including cotton, polyester, nylon, and blended materials.

Smooth Printing Experience

Professional-grade DTF films ensures stable ink absorption during the printing process. The coating is optimized for white and colored inks, allowing each layer to cure properly. This results in bold, high-definition prints that capture every detail of your artwork.

The film also performs well under various temperature and humidity conditions, minimizing print errors such as cracking or ink bleeding. This consistency makes it ideal for businesses aiming to maintain production speed without compromising quality.

Durability and Wash Resistance

A major advantage of using the best DTF films is its outstanding durability. Prints created with this film resist fading, peeling, and cracking, even after repeated washing. The strong adhesive ensures that designs remain flexible and soft to the touch, offering a comfortable feel on garments.

This durability is especially valuable for apparel items that undergo frequent use, such as sportswear, work uniforms, or promotional clothing. With proper application, prints stay bright and sharp over time, maintaining a professional appearance that customers love.

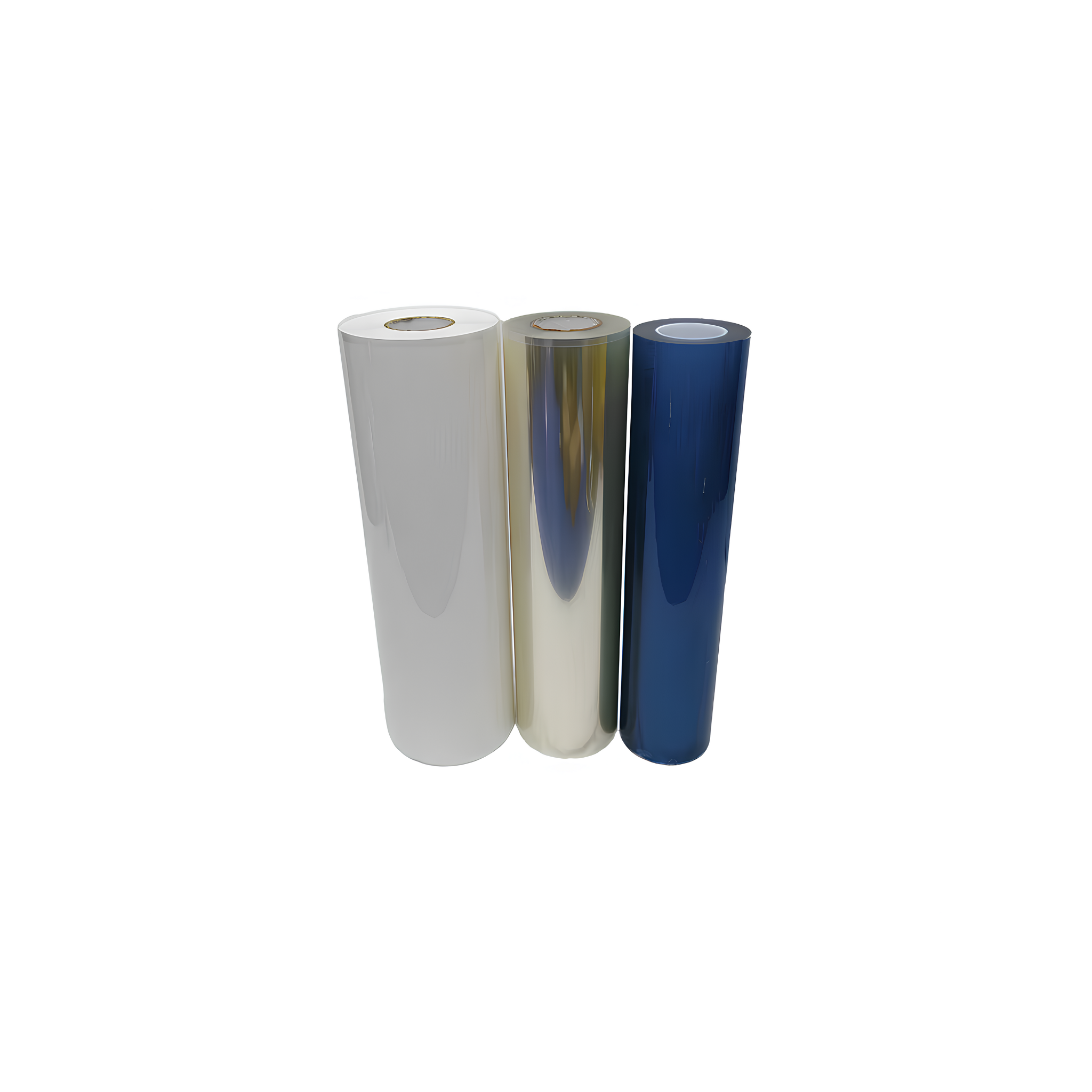

Compatibility and Ease of Use

The best DTF films is designed for compatibility with most DTF printers and inks available in the market. It supports both hot and cold peel options, allowing users to choose the workflow that best suits their production needs.

Using the film is simple: print your design, apply adhesive powder, cure the print, and press it onto the fabric. The easy-release layer ensures a smooth peel, reducing waste and saving time during production. Even beginners can achieve excellent results with minimal effort.

Vibrant Color Reproduction

Color quality is one of the defining features of premium DTF films. The coating layer ensures that inks retain their full intensity and opacity after transfer. Whites stay crisp, blacks remain deep, and gradients appear smooth and natural.

This makes it a great choice for detailed artwork, photo-based designs, and multi-color graphics. Whether printing logos, illustrations, or full-color images, the best DTF film delivers flawless results that meet professional standards.

Cost-Effective for Businesses

Choosing the best DTF films is not only about print quality but also about efficiency. The consistent release properties minimize errors, reducing wasted materials and reprints. This reliability translates to lower production costs over time.

Bulk purchasing options also make it an economical choice for print shops handling large orders. With less waste, faster printing, and high customer satisfaction, it’s a smart investment for growing businesses.

Versatility in Application

Another reason professionals prefer top-grade DTF films is their versatility. The film works perfectly on various garment types and accessories. It can be applied to T-shirts, hoodies, tote bags, caps, and even home décor fabrics.

Its adaptability allows designers to experiment with creative applications while ensuring consistent results. Whether you’re producing one custom shirt or a full production run, you can trust the film to perform reliably.

Eco-Friendly and Safe Production

Many of the best DTF films are produced with eco-conscious materials that reduce environmental impact. They are designed to work with water-based DTF inks, which are non-toxic and safe for both users and the environment.

This commitment to sustainability ensures that you can deliver top-quality prints while maintaining an environmentally responsible workflow.

Conclusion

The Best DTF Films stands out as a vital component for anyone involved in garment customization and digital printing. Its superior coating, strong adhesion, and brilliant color performance guarantee professional results every time. Durable, cost-effective, and easy to use, this film is perfect for creating vibrant and long-lasting prints on any fabric type.

Whether you’re running a printing business or exploring creative projects, investing in the best DTF film ensures consistent, top-tier results. Enjoy smooth application, outstanding durability, and professional-grade color reproduction with every print — a must-have for every modern printer.

Visit Our Site

Please Click to get P604U - UV DTF Printer