What Does DTF Transfer Mean

What Does DTF Transfer Mean: A Professional Guide

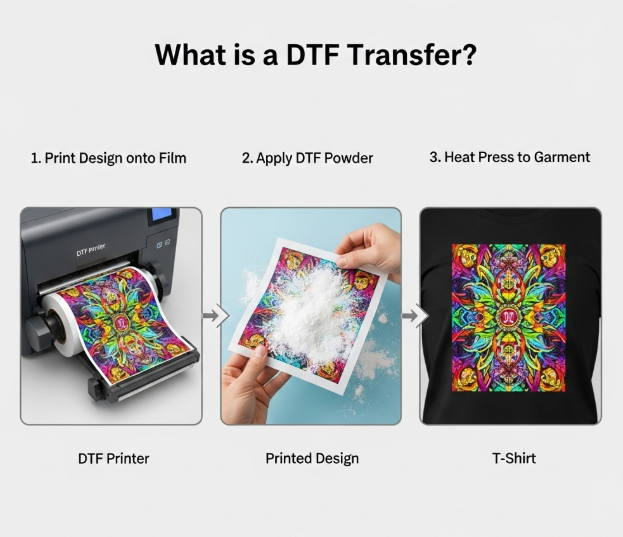

The custom apparel industry is evolving rapidly due to new digital technologies. Many creators and business owners now ask, What Does DTF Transfer Mean? Standing for Direct-to-Film, this process involves printing designs onto a specialized film carrier. You then transfer that image onto fabric using heat and pressure. This method has quickly become a global industry standard for high-quality custom clothing. It offers a perfect balance of durability, vibrant detail, and production speed. This guide explains how the technology works and why it is so effective for modern brands.

Defining the Core Technology

To truly understand What Does DTF Transfer Mean, you should look at the name itself. The process literally moves pigment ink from a digital file to a physical film surface.

The Printing Stage A specialized inkjet printer applies textile pigments to a coated PET film. The machine prints the colorful CMYK layer first to create the artwork. Immediately after, it covers the design with a thick white ink base. This white layer is crucial for opacity because it allows colors to remain visible on dark fabrics.

The Adhesive Stage While the ink remains wet, a hot-melt adhesive powder is applied across the film. This powder sticks specifically to the printed areas and acts as a bonding agent. Once heated, the powder melts into a powerful glue. This chemical reaction creates the bridge between the ink and the garment fibers.

How the Workflow Operates

Defining What Does DTF Transfer Mean requires looking at the specific production steps. The entire process follows a very logical and efficient sequence.

-

Artwork Preparation: Create a high-resolution digital design with a transparent background.

-

Film Printing: Transfer the image to a specialized, ink-receptive PET film.

-

Powder Coating: Apply hot-melt adhesive powder to the wet white ink layer.

-

Curing: Use a heat source to melt the powder into a solid, tacky layer.

-

Heat Pressing: Bond the film to the fabric using a professional heat press.

-

Peeling: Remove the plastic carrier to reveal the finished, vibrant print.

Why DTF is Leading the Industry

Many entrepreneurs ask What Does DTF Transfer Mean for their overall production versatility. It offers several unique benefits over traditional screen printing or vinyl cutting.

Unlimited Material Options Sublimation is limited to polyester materials only. However, DTF works on almost any material imaginable. You can print on cotton, nylon, silk, and even treated leather. It also works perfectly on 50/50 blends and synthetic fabrics. This flexibility allows brands to expand their product lines without buying new equipment.

High-Quality Results The prints are incredibly sharp and full of color. Because of the solid white base, even fine lines remain visible on black or navy shirts. The final product is soft to the touch and remains very stretchable. This elasticity prevents the design from cracking after several washes. To achieve the best longevity, always use professional supplies. You can check the

The Essential Components of the System

To truly grasp What Does DTF Transfer Mean, you must identify the necessary tools. Each component ensures the transfer lasts for the life of the garment.

-

PET Film: A stable, heat-resistant carrier for the design.

-

Textile Inks: Pigments specifically designed to bond with fabric fibers.

-

Adhesive Powder: The glue that secures the ink to the shirt.

-

RIP Software: The program that manages color profiles and white ink density.

The quality of the powder determines how well the shirt withstands a washing machine. Using premium materials is always a smart investment for your brand's reputation. You can find these in the

Maintenance for Long-Term Success

Owning a DTF printer requires a specific and consistent care routine. Since the ink contains heavy pigments, it can settle and clog if the machine sits idle.

Daily Maintenance Rituals Shake the white ink tanks every single day to keep the pigments mixed. Running a nozzle check is also vital for preventing expensive printhead clogs. If the ink dries inside the machine, it can lead to costly repairs. Keeping the system clean is the real secret to achieving professional results every time.

Cleaning Solutions Using specialized tools makes the maintenance process much easier. You can find everything you need in the

Expanding the Definition: UV DTF

Now that you know What Does DTF Transfer Mean for clothing, consider the world of hard surfaces. This is where UV DTF technology becomes relevant.

Hard Surface Customization UV DTF is specifically designed for items like mugs, glass, metal, and electronics. It uses UV-curable inks that are extremely durable and scratch-resistant. Unlike fabric transfers, these do not require any heat application. You simply peel and stick the design directly onto the surface.

Productivity with Gang Sheets For large orders, using

Conclusion

So, What Does DTF Transfer Mean? It represents total creative freedom and professional-grade quality. This technology allows you to print any design on almost any surface with ease. It is affordable enough for small home shops yet fast enough for large-scale factories. By using the right inks and powders, you can create products that your customers will love for years. Maintain your equipment daily, and you will enjoy a successful printing business in the custom apparel world.

Join our growing community online to stay updated with the latest trends and innovations in the printing world. Follow us on