Transforming Ideas into Stunning Print Realities: DTF Ink Revolution

Transforming Ideas into Stunning Print Realities: The DTF Ink Revolution

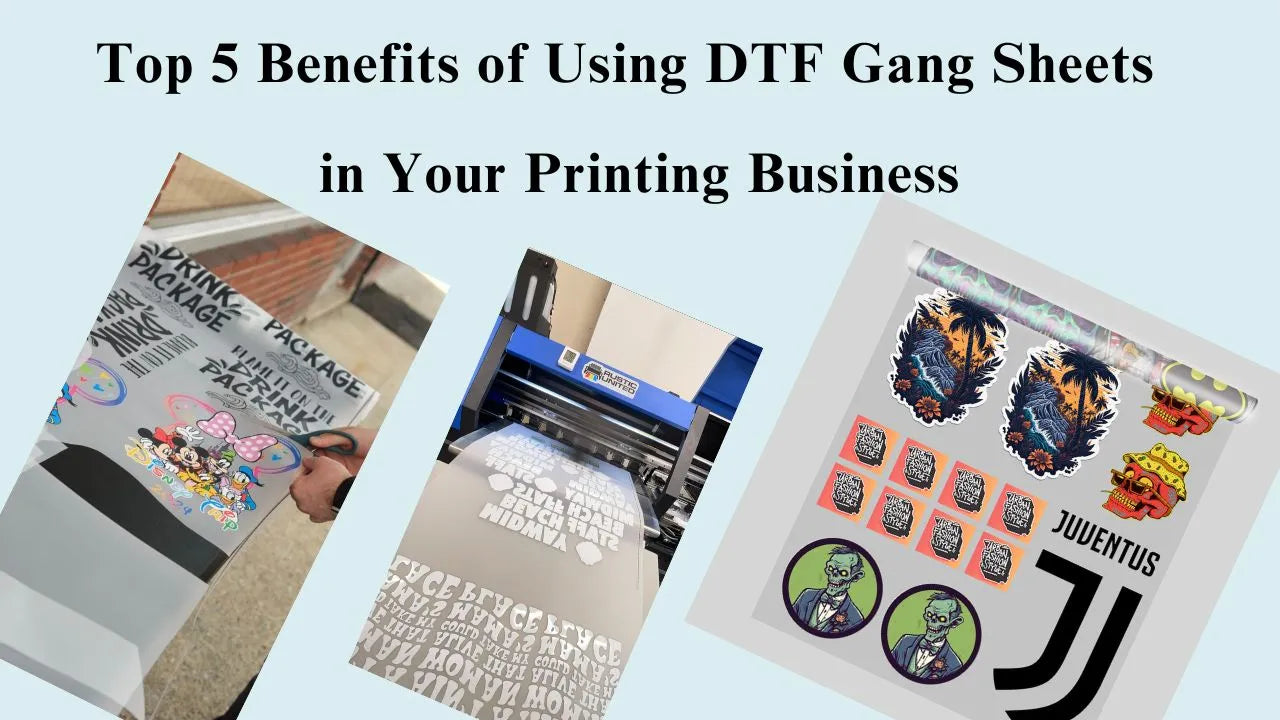

Custom printing is essential in industries like fashion, promotions, and gifts. DTF Ink Revolution (Direct-to-Film ink) has emerged as a game-changing technique, making it easier to create vibrant, durable prints on a variety of materials. This innovation is helping businesses and entrepreneurs turn ideas into stunning print realities.

What is DTF Ink? DTF Ink Revolution

DTF ink is used in DTF printing, where designs are printed onto a special film and transferred onto fabrics using heat. The result is vibrant, durable, and high-quality prints on materials like cotton, polyester, leather, and more.

Why DTF Ink is a Game-Changer - DTF Ink Revolution

-

Vibrant Colors & Detail: DTF ink produces sharp, colorful prints, capturing intricate designs with precision.

-

Durability: Prints stay vibrant even after many washes, ensuring long-lasting quality.

-

Material Compatibility: Works on fabrics, leather, canvas, and even non-textile items.

-

Faster Turnaround: DTF printing is quicker than traditional methods, allowing for rapid production and delivery.

How DTF Ink Transforms Custom Products - DTF Ink Revolution

-

Custom Apparel: Perfect for printing t-shirts, hoodies, and hats with custom designs.

-

Promotional Merchandise: Create branded items like bags and mugs to expand your brand's reach.

-

Personalized Gifts: Customize products for special events like weddings or birthdays.

The Future of Custom Printing with DTF Ink Revolution

DTF ink is leading the way in personalized products. Its versatility, speed, and durability make it ideal for businesses looking to stay competitive. As demand for custom products grows, DTF ink will become an essential tool for custom printing.

Why Embrace DTF Ink?

-

Cost-Effective: Lower production costs than screen printing, making it ideal for small businesses.

-

No Minimum Orders: Perfect for both single items and bulk orders.

-

Eco-Friendly: Many DTF inks are water-based, reducing environmental impact.

Final Thoughts

DTF ink is revolutionizing custom printing by offering vibrant, durable, and versatile solutions for businesses. Whether in fashion, promotional items, or personalized gifts, DTF ink brings your ideas to life with precision and speed. The future of custom printing is bright with DTF ink leading the way.

1. What is Direct-to-Film (DTF) Ink Technology?

DTF Ink Technology involves printing designs onto a special transfer film using high-quality inks. The design is then transferred to various materials like fabric, canvas, and other surfaces using a heat press. This technology offers vibrant, durable prints on both light and dark fabrics.

2. How does DTF Ink Technology work?

The process begins by printing your design on a special film using DTF ink. Once the design is printed, the film is transferred onto the target material using a heat press, where the ink bonds with the fibers of the material, resulting in a high-quality print.

3. What materials can be used with DTF Ink Technology?

DTF Ink Technology is versatile and works on a variety of materials, including cotton, polyester, leather, canvas, and even non-textile surfaces like wood and ceramics. It is perfect for custom apparel, promotional items, and personalized gifts.

4. Is DTF Ink durable?

Yes, prints made with DTF ink are highly durable. The ink bonds well with the fabric, ensuring that the designs remain vibrant and intact even after multiple washes. This makes DTF printing ideal for long-lasting custom products.

5. What are the advantages of using DTF Ink Technology over other printing methods?

DTF Ink Technology offers several advantages:

- Faster production time compared to screen printing

- More vibrant and high-resolution prints

- Ability to print on both light and dark fabrics

- Lower setup costs than traditional printing methods

- Works on a wide range of materials

6. Can I print intricate designs with DTF Ink Technology?

Yes! DTF Ink Technology is excellent for printing intricate, detailed designs. The high resolution and vibrant colors allow for the reproduction of even the most complex artwork with clarity and precision.

7. How long does it take to print using DTF Ink Technology?

The process is relatively quick. Once the design is created and the film is printed, transferring the design onto the material using a heat press typically takes just a few seconds to a minute, depending on the material and design size.

8. Is DTF printing eco-friendly?

Many DTF inks are water-based, making them a more eco-friendly option compared to solvent-based inks. They have a lower environmental impact, producing fewer harmful emissions and being safer for use in custom printing.

9. Can DTF Ink be used for small-scale orders?

Absolutely! One of the key benefits of DTF Ink Technology is that there is no minimum order requirement. Whether you need to print a single item or a large batch, DTF printing is ideal for both small and large-scale orders.

10. How does DTF Ink compare to other printing techniques like DTG or screen printing?

While DTG (Direct-to-Garment) printing and screen printing are widely used, DTF Ink Technology offers several advantages:

- DTF printing is faster and more cost-effective for smaller runs.

- It doesn’t require pre-treatment of fabrics like DTG.

- DTF ink works on a wider range of materials, including non-textile surfaces, which DTG cannot handle.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.